Benefits of Using Rigid-Flex PCBs in Electronic Devices

Rigid-flex PCBs, or printed circuit boards, have become increasingly popular in the electronics industry due to their unique design and numerous advantages.

These boards combine the benefits of both rigid and flexible PCBs, allowing for greater flexibility in design and improved performance in electronic devices.

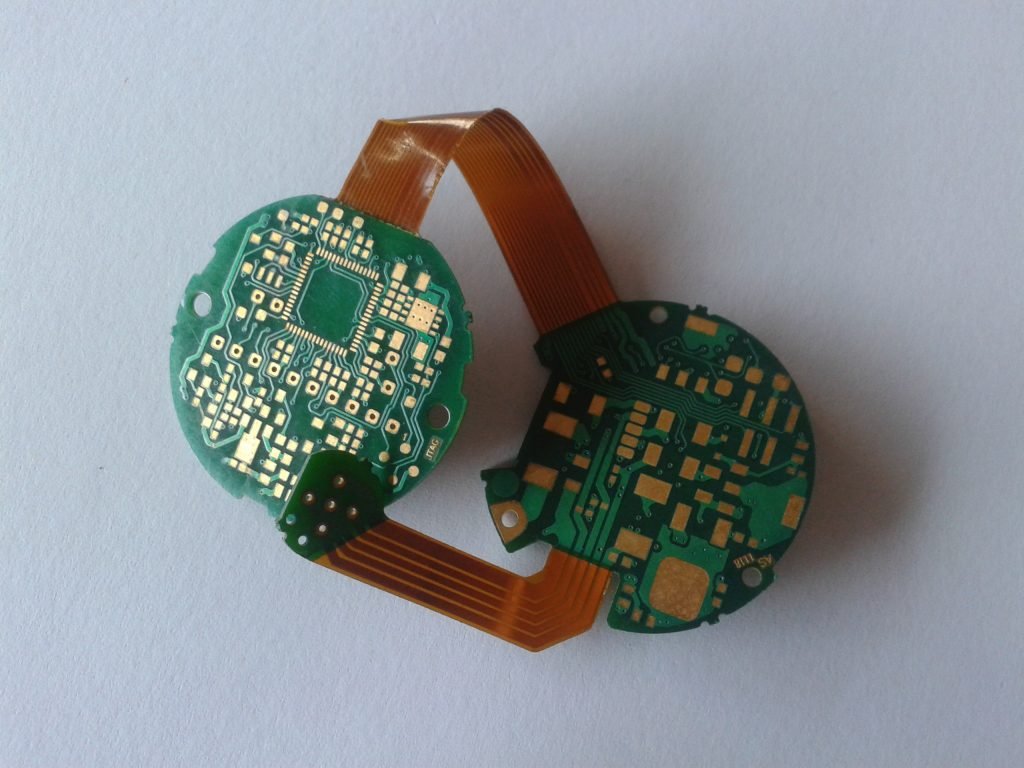

One of the key principles of rigid-flex PCB design is the integration of rigid and flexible sections within the same board.

This allows for the board to be bent or folded to fit into tight spaces or odd shapes, making it ideal for devices with limited space or complex designs. The rigid sections provide stability and support for components, while the flexible sections allow for movement and flexibility.

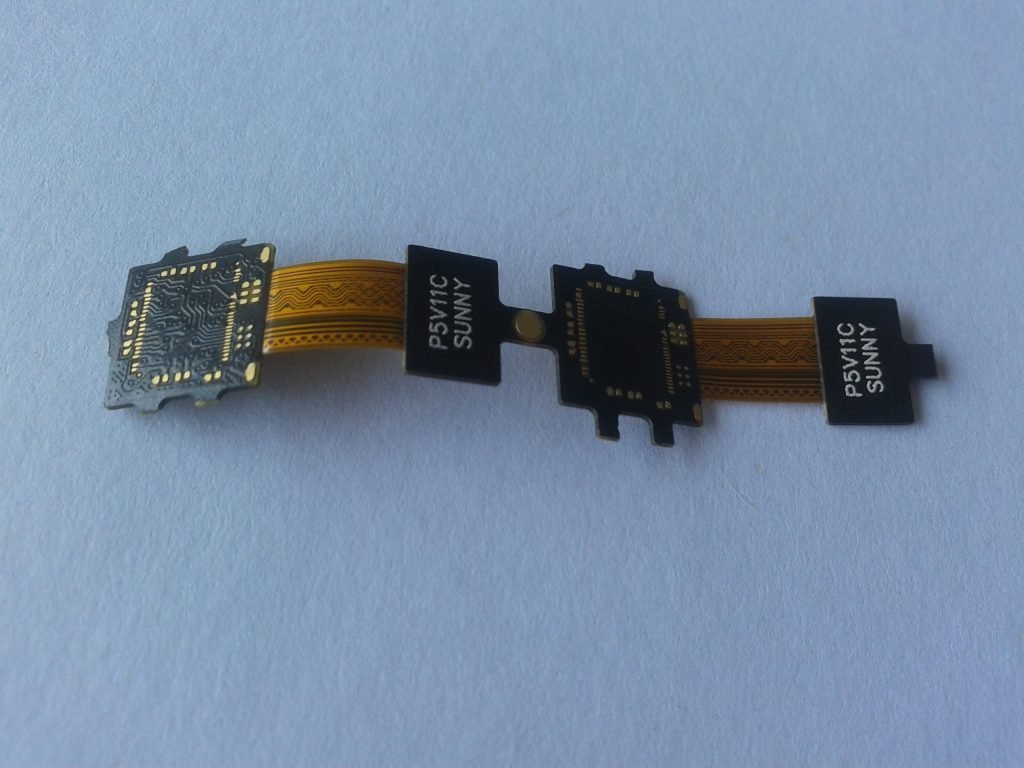

Another important principle of rigid-flex PCB design is the use of high-quality materials and manufacturing processes.

Rigid-flex PCBs are typically made from materials such as polyimide or FR4, which are known for their durability and reliability.

These materials are also able to withstand high temperatures and harsh environments, making them ideal for a wide range of applications.

In addition to their unique design principles, rigid-flex PCBs offer a number of advantages over traditional PCBs.

One of the main benefits of using rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible sections into a single board, designers are able to create more compact and lightweight devices without sacrificing performance or functionality.

Rigid-flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The flexible sections of the board are able to absorb shock and vibration, reducing the risk of damage to components and extending the lifespan of the device. Additionally, the use of high-quality materials and manufacturing processes ensures that rigid-flex PCBs are able to withstand harsh conditions and extreme temperatures, making them ideal for a wide range of applications.

Another advantage of using rigid-flex PCBs is their ability to simplify the assembly process.

By combining multiple boards into a single unit, designers are able to reduce the number of interconnects and solder joints, which can help to improve overall reliability and reduce the risk of failure.

This can also help to reduce manufacturing costs and lead times, making rigid-flex PCBs a cost-effective solution for many electronic devices.

Overall, rigid-flex PCBs offer a number of advantages over traditional PCBs, including improved flexibility, reliability, and durability.

By combining rigid and flexible sections into a single board, designers are able to create more compact and lightweight devices without sacrificing performance or functionality.

Additionally, the use of high-quality materials and manufacturing processes ensures that rigid-flex PCBs are able to withstand harsh conditions and extreme temperatures, making them ideal for a wide range of applications.