Understanding Rigid-Flex PCB Design Costs: Key Factors and Breakdown

Understanding rigid-flex PCB design costs is essential for businesses and engineers looking to incorporate this innovative technology into their products.

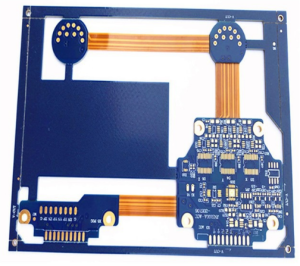

Rigid-flex printed circuit boards (PCBs) combine the functionality of both rigid and flexible circuits, offering versatility that has become crucial in modern electronics.

However, the costs associated with their design and production can vary significantly based on several factors.

In the following sections, we’ll break down these key considerations that influence rigid-flex PCB design costs.

The Complexity of Design

One of the most significant factors affecting the cost of rigid-flex PCB design is the complexity involved.

The design process for rigid-flex PCBs typically requires advanced engineering capabilities due to the multiple layers often involved and the need for careful planning of the flex areas.

Layer Count

The number of layers plays a crucial role in determining the overall cost.

Rigid-flex boards often have a higher layer count compared to their rigid or flexible counterparts.

Each layer adds to the complexity and resources required for fabrication, which in turn increases the expenses.

If you are considering a design with multiple rigid and flexible segments, you can expect a corresponding rise in costs.

Design Considerations

Adding to the complexity are the design considerations that must be accounted for during the engineering phase. These may include:

- Routing requirements: Efficient routing is critical to ensure that signals can transfer seamlessly between rigid and flexible sections.

Complex routing can lead to increased design time and costs. - Impedance control: Ensuring that signals maintain integrity often requires specialized materials and precise construction techniques, which can drive up costs.

Material Choice

Another essential element influencing rigid-flex PCB design costs is the choice of materials.

The substrate materials for these boards differ significantly from standard PCBs, as they must withstand bending and flexing without compromising functionality.

Flexible Material Options

Flexible substrates, such as polyimide, are commonly used in rigid-flex designs.

These materials are more expensive than traditional FR-4 material often used in rigid boards.

Alternately, using high-frequency or high-temperature materials can further escalate costs, particularly for applications in aerospace or medical devices.

Lamination Processes

The lamination process also affects costs. Unlike standard PCBs, rigid-flex PCBs require careful lamination techniques to maintain the integrity of both rigid and flexible areas.

The complexity and precision needed for multi-layer stacking contribute additional labor and material costs.

Manufacturing Techniques

Understanding rigid-flex PCB design costs also involves delving into the manufacturing techniques employed.

These boards typically require specialized equipment and processes, which can lead to higher production costs.

Production Volume

The quantity of boards ordered can influence per-unit costs significantly.

Smaller production runs are often more expensive per unit due to the initial setup costs.

Conversely, larger volumes benefit from economies of scale, leading to reduced per-unit costs.

Prototyping and Testing

Before moving to full-scale production, prototyping and testing are crucial steps in the manufacturing process.

High-quality prototypes often come with additional expense, yet they are vital for verifying the design’s performance and ensuring reliability in end-use.

Regulatory and Compliance Costs

For industries such as medical, automotive, or aerospace, compliance with stringent regulations adds another layer of costs to rigid-flex PCB designs.

Meeting these standards often requires additional testing and documentation, contributing to both time and financial investment.

Certifications

Achieving necessary certifications—for example, ISO or IPC guidelines—can incur further costs.

This investment ensures that your rigid-flex PCBs meet the required safety and performance benchmarks, which is critical in regulated industries.

Conclusion

Understanding rigid-flex PCB design costs is a multi-dimensional endeavor that requires careful consideration of various factors: complexity of design, material choice, manufacturing techniques, and compliance requirements. By grasping these elements, businesses can make more informed decisions when planning their projects, ensuring they allocate appropriate resources for successful implementation.

Ultimately, while the initial costs can be higher compared to traditional PCB designs, the substantial benefits of integrating rigid-flex technology—such as reduced size, enhanced performance, and improved reliability—often justify the investment in the long run. As electronics continue to evolve, rigid-flex PCBs will remain crucial offerings, blending durability with flexibility in innovative designs.