Understanding Rigid-Flex PCB Design

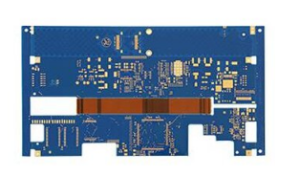

Rigid-flex PCBs, a hybrid of rigid and flexible PCBs, offer a unique solution for applications that require a combination of compact form factor, durability, and flexibility.

The design integrates rigid sections with flexible circuits, providing enhanced reliability and improved mechanical performance.

While the initial cost of implementing rigid-flex PCB design may be higher than traditional PCBs, the long-term benefits often outweigh the upfront investment.

Cost Considerations for Rigid-Flex PCB Design

One of the key advantages of rigid-flex PCB design is the reduction in overall assembly costs.

By eliminating the need for additional connectors and cables, rigid-flex PCBs streamline the assembly process, reducing labor costs and minimizing the risk of human error.

Additionally, the compact nature of rigid-flex designs can lead to cost savings in terms of material usage and board size, contributing to a more efficient and cost-effective manufacturing process.

Comparative Analysis: Traditional PCBs vs. Rigid-Flex PCBs

When comparing the overall cost of traditional PCBs with rigid-flex PCBs, several factors come into play.

Traditional PCBs, while typically more affordable in terms of upfront material costs, may incur higher assembly and maintenance expenses due to the complexity of integrating multiple boards and connectors.

In contrast, rigid-flex PCBs offer a consolidated solution that can result in long-term cost savings by reducing the need for additional components and minimizing the risk of mechanical failure.

Optimizing Cost Efficiency in PCB Design

To maximize cost efficiency in PCB design, it is essential to consider the specific requirements of the application, the expected lifecycle of the product, and the scalability of the design.

While traditional PCBs may be suitable for certain applications that do not require flexibility or compactness, rigid-flex PCBs offer a tailored solution for industries such as aerospace, medical devices, and automotive electronics, where reliability and space optimization are critical factors.

Conclusion

In conclusion, the cost benefits of rigid-flex PCB design compared to traditional PCBs are contingent on various factors, including production volume, design complexity, and overall application requirements.

While the initial investment in rigid-flex PCBs may be higher, the long-term advantages in terms of reliability, space-saving, and assembly efficiency can lead to significant cost savings over the product lifecycle.

By conducting a thorough analysis of the cost implications and benefits of each PCB design option, companies can make informed decisions that align with their budgetary constraints and project objectives.