Benefits of Using RigidFlex PCBs in Electronic Devices

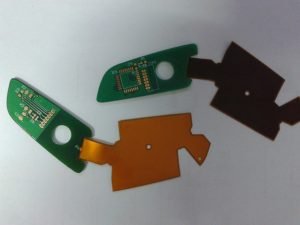

Rigid-flex PCBs, or printed circuit boards, have become increasingly popular in the electronics industry due to their numerous benefits and advantages.

These innovative PCBs combine the flexibility of flexible circuits with the durability and reliability of rigid boards, making them ideal for a wide range of electronic devices. In this article, we will explore the benefits of using rigid-flex PCBs in electronic devices and discuss some best practices for designing them.

One of the key benefits of using rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By combining the flexibility of flexible circuits with the rigidity of traditional PCBs, designers can create compact and lightweight devices that are easier to handle and more aesthetically pleasing. This can be particularly advantageous in applications where space is limited, such as in wearable technology, medical devices, and aerospace equipment.

In addition to their compact size, rigid-flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The flexible portions of the board are less prone to damage from bending or vibration, making them ideal for applications where the device

may be subject to physical stress or movement. This increased durability can help to extend the lifespan of electronic devices and reduce the need for

costly repairs or replacements.

Another benefit of using rigid-flex PCBs is their ability to simplify the assembly process. By combining multiple PCBs into a single rigid-flex design, manufacturers can reduce the number of components and connections required, leading to faster and more efficient assembly.

This can help to streamline the production process and reduce manufacturing costs, making rigid-flex PCBs a cost-effective solution for many electronic devices.

Furthermore, rigid-flex PCBs offer improved signal integrity and electrical performance compared to traditional PCBs. The flexible portions of the board can be designed to minimize signal loss and interference, resulting in better overall performance and reliability. This can be particularly important in high-speed applications, such as data communication and signal processing, where even small disruptions in signal quality can have a significant impact on performance.

When designing rigid-flex PCBs, there are several best practices that designers should keep in mind to ensure optimal performance and reliability.

One important consideration is to carefully plan the layout of the board to minimize stress on the flexible portions and ensure proper alignment of components. Designers should also pay close attention to the materials used in the construction of the board, selecting high-quality materials that are compatible with the intended application and environment.

Additionally, designers should consider the thermal management of the board, ensuring that heat generated by components is properly dissipated to prevent overheating and damage. This may involve incorporating thermal vias, heat sinks, or other cooling mechanisms into the design of the board. By carefully considering these factors during the design process, designers can create rigid-flex PCBs that offer optimal performance, reliability, and durability.

In conclusion, rigid-flex PCBs offer a wide range of benefits for electronic devices, including reduced size and weight, improved reliability and durability, simplified assembly, and enhanced signal integrity. By following best practices for designing rigid-flex PCBs, designers can create high-quality boards that meet the specific requirements of their applications and deliver superior performance and reliability. With their unique combination of flexibility and rigidity, rigid-flex PCBs are sure to play an important role in the future of electronic device design.