Top 10 Rigid-Flex PCB Design Guidelines for Reliable Circuits

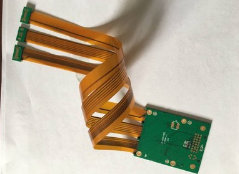

Rigid-flex PCB design is pivotal in creating reliable circuits that can withstand various environmental and operational conditions.

As electronic devices become increasingly compact and sophisticated, understanding the intricacies of rigid-flex PCB design is essential for engineers and manufacturers alike.

In this article, we will explore ten crucial guidelines that will help you design rigid-flex printed circuit boards effectively, ensuring reliability and performance.

1. Understand the Material Properties

The first step in designing a rigid-flex PCB is to comprehend the various materials involved. Rigid-flex PCBs typically consist of a combination of rigid and flexible substrates.

Common materials like FR-4, polyimide, and copper foils have different thermal properties, mechanical strengths, and flexural abilities.

Understanding these properties will guide you in selecting the right materials for your application.

2. Define the Flex Range

When designing a rigid-flex circuit, defining the flex range is crucial. Determine how much bending will occur during operation and choose the flexible regions of the PCB accordingly.

A well-defined flex range will not only optimize circuit performance but also prolong the lifespan of the PCB by minimizing stress and strain in critical areas.

3. Maintain Signal Integrity

Signal integrity is paramount in any electronic design, and rigid-flex PCBs are no exception. Ensure that signal traces are appropriately sized and spaced to minimize crosstalk and electromagnetic interference (EMI).

Use proper grounding techniques and consider the impedance of transmission lines to maintain clean signal paths throughout the circuit.

4. Optimize Layer Stacking

Layer stacking is significant in the design of rigid-flex PCBs. Ensure that you balance the layers of rigid and flexible sections effectively.

In general, flexible layers should be placed in the inner layers to protect them from external damage. A well-structured layer stack will improve circuit performance and reliability.

5. Design for Manufacturability

While creativity in design is essential, one must always keep manufacturability in mind. Complex designs can lead to manufacturing difficulties that might compromise the reliability of the finished product.

Utilize standard sizes for traces and pads, and limit the number of blind and buried vias to ease manufacturing challenges.

6. Implement Proper Testing Procedures

Testing is an integral part of the design process. Implement rigorous testing procedures to evaluate the performance of your rigid-flex PCB.

Conduct both functional and environmental tests, including mechanical stress tests, thermal cycling tests, and humidity tests, to ensure the circuit can withstand the conditions it will face in operation.

7. Focus on Trace Routing

Effective trace routing is fundamental in rigid-flex PCB design. Keep traces as short as possible to minimize the inductance and resistive losses.

Additionally, avoid sharp corners and aggressive bends, as these can induce mechanical stress and lead to failures. Instead, design gentle curves to maintain flexibility without compromising performance.

8. Explore Via Options

Choosing the right type of vias is critical in rigid-flex PCB design. Consider using micro vias, blind vias, and buried vias based on your layout and space requirements.

While micro vias can save space, they may also require more sophisticated manufacturing techniques, so weighing the benefits against the potential challenges is essential.

9. Design for Thermal Management

Thermal performance is often overlooked in rigid-flex PCB design. High-density components can generate significant heat, which must be managed to maintain circuit reliability.

Include thermal vias and consider using heat sinks or thermal pads in your design to dissipate heat effectively.

10. Collaborate with Manufacturers

Finally, maintaining communication with your PCB manufacturer throughout the design process ensures a smoother transition from design to production.

They can offer insights into material selection, fabrication capabilities, and potential issues that may arise during manufacturing.

By collaborating closely, you can refine your design to meet industry standards and enhance overall reliability.

Conclusion

Designing reliable rigid-flex PCBs necessitates attention to detail and a deep understanding of the interaction between materials, manufacturing processes, and electrical performance.

By adhering to these ten guidelines, you can enhance the effectiveness of your rigid-flex PCB design and ensure that your circuits perform reliably in various applications.

This knowledge not only fosters quality output but also instills confidence in the durability and efficiency of your electronic devices.