Benefits of Rigid-Flex PCB Assembly

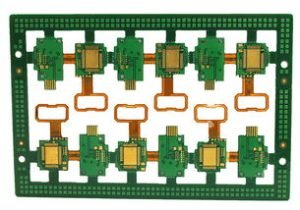

Rigid-flex PCB assembly is a specialized manufacturing process that combines rigid and flexible circuit boards into a single unit.

This innovative technology offers numerous benefits, making it an attractive option for a wide range of applications.

In this article, we will explore the advantages of rigid-flex PCB assembly and how manufacturers can overcome the challenges associated with this complex process.

One of the key benefits of rigid-flex PCB assembly is its ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible circuit boards, designers can create compact and lightweight products that are ideal for space-constrained applications.

This can lead to significant cost savings, as smaller and lighter devices require fewer materials and components.

Another advantage of rigid-flex PCB assembly is its improved reliability and durability.

Traditional PCBs are prone to mechanical stress and vibration, which can lead to solder joint failures and other reliability issues.

Rigid-flex PCBs, on the other hand, are more resistant to these types of stresses, making them ideal for high-reliability applications such as aerospace, medical, and automotive electronics.

In addition to improved reliability, rigid-flex PCB assembly offers enhanced design flexibility.

Designers can create complex layouts that would be impossible with traditional PCBs, allowing for more efficient use of space and improved signal integrity. This flexibility also enables manufacturers to reduce the number of interconnects and connectors, further improving reliability and reducing costs.

Despite these benefits, rigid-flex PCB assembly presents several challenges for manufacturers.

One of the main challenges is the complexity of the manufacturing process.

Rigid-flex PCBs require specialized equipment and expertise, making them more difficult to produce than traditional PCBs.

Manufacturers must invest in training and equipment to ensure that they can meet the high quality standards required for rigid-flex PCB assembly.

Another challenge is the increased risk of defects and failures.

The combination of rigid and flexible materials can lead to issues such as delamination, cracking, and solder joint failures.

Manufacturers must carefully control the manufacturing process to minimize these risks and ensure that the final product meets the required specifications.

To overcome these challenges, manufacturers can take several steps to improve the quality and reliability of rigid-flex PCB assembly.

One approach is to work closely with suppliers to ensure that materials and components meet the necessary specifications.

By using high-quality materials and components, manufacturers can reduce the risk of defects and failures in the final product.

Manufacturers can also invest in advanced testing and inspection equipment to identify and address potential issues early in the manufacturing process.

By conducting thorough testing and inspection, manufacturers can ensure that rigid-flex PCBs meet the required quality standards and perform reliably in the field.

In conclusion, rigid-flex PCB assembly offers numerous benefits for manufacturers and designers, including reduced size and weight, improved reliability, and enhanced design flexibility.While the manufacturing process presents challenges, manufacturers can overcome these obstacles by investing in training, equipment, and quality control measures.

By taking these steps, manufacturers can produce high-quality rigid-flex PCBs that meet the demands of today’s complex electronic devices.