Benefits of Rigid-Flex PCB Assembly

In the fast-paced world of modern electronics, the demand for smaller, lighter, and more flexible devices is ever-increasing.

As a result, manufacturers are constantly seeking innovative solutions to meet these demands. One such solution that has gained popularity in recent years is rigid-flex PCB assembly.

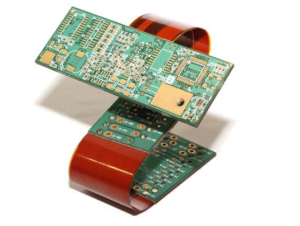

Rigid-flex PCBs combine the best of both rigid and flexible circuit boards, offering the benefits of both in a single package.

These boards consist of multiple layers of flexible circuitry that are interconnected by rigid sections, allowing for increased flexibility and durability while maintaining the structural integrity necessary for many electronic devices.

One of the key benefits of rigid-flex PCB assembly is its ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, rigid-flex PCBs allow for more compact and lightweight designs, making them ideal for applications where space is at a premium.

Additionally, rigid-flex PCBs offer improved reliability and durability compared to traditional rigid PCBs.

The flexible sections of the board help to absorb shock and vibration, reducing the risk of damage to the components and extending the lifespan of the device. This increased durability makes rigid-flex PCBs particularly well-suited for applications in harsh environments or high-stress situations.

Another advantage of rigid-flex PCB assembly is its ability to simplify the manufacturing process.

By combining multiple circuit layers into a single board, manufacturers can reduce the number of components and connections required, streamlining the assembly process and reducing the risk of errors. This not only saves time and money during production but also improves the overall quality and consistency of the finished product.

Furthermore, rigid-flex PCBs offer greater design flexibility compared to traditional rigid boards.

The ability to bend and shape the board allows for more creative and innovative designs, enabling manufacturers to create products that would be impossible with rigid PCBs alone. This flexibility opens up a world of possibilities for designers, allowing them to push the boundaries of what is possible in electronic device design.

In addition to these practical benefits, rigid-flex PCB assembly also offers cost savings in the long run.

While the initial investment in rigid-flex PCBs may be higher than traditional rigid boards, the increased durability and reliability of these boards can lead to lower maintenance and replacement costs over time. This can result in significant savings for manufacturers, making rigid-flex PCB assembly a cost-effective solution in the long term.

Overall, rigid-flex PCB assembly offers a wide range of benefits for manufacturers looking to meet the demands of modern electronics.

From reduced size and weight to improved reliability and durability, rigid-flex PCBs provide a versatile and innovative solution for a variety of applications.

With their ability to simplify the manufacturing process, increase design flexibility, and offer long-term cost savings, rigid-flex PCBs are quickly becoming the go-to choice for manufacturers seeking to stay ahead in the ever-evolving world of electronics.