Benefits of Rigid-Flex PCB Assembly

Rigid-flex PCB assembly is a popular choice for many electronic devices due to its numerous benefits.

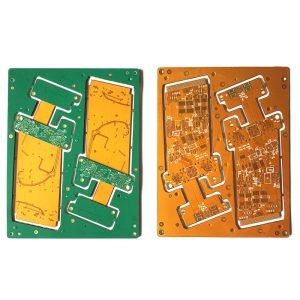

This type of PCB combines the flexibility of a flexible PCB with the rigidity of a rigid PCB, offering a unique solution for applications that require both flexibility and durability. In this article, we will explore the benefits of rigid-flex PCB assembly and how it ensures quality and durability in electronic devices.

One of the key benefits of rigid-flex PCB assembly is its ability to reduce the overall size and weight of electronic devices.

By combining the flexibility of a flexible PCB with the rigidity of a rigid PCB, designers can create compact and lightweight PCBs that can fit into tight spaces and withstand harsh environments.

This makes rigid-flex PCBs ideal for applications where space is limited, such as in medical devices, aerospace systems, and wearable technology.

Another benefit of rigid-flex PCB assembly is its reliability and durability.

The combination of flexible and rigid materials in a single PCB design results in a more robust and resilient circuit board that can withstand bending, twisting, and vibration.

This makes rigid-flex PCBs ideal for applications that require high reliability and long-term performance, such as in automotive electronics, industrial control systems, and military equipment.

In addition to their compact size and durability, rigid-flex PCBs also offer improved signal integrity and reduced electromagnetic interference.

The flexible sections of the PCB can be used to route high-speed signals between rigid sections, reducing signal loss and improving overall performance.

This makes rigid-flex PCBs ideal for applications that require high-speed data transmission, such as in telecommunications equipment, networking devices, and consumer electronics.

Furthermore, rigid-flex PCB assembly can also simplify the manufacturing process and reduce assembly costs.

By combining multiple PCBs into a single rigid-flex design, manufacturers can reduce the number of components, connectors, and solder joints required, resulting in a more streamlined and cost-effective assembly process.

This can lead to faster production times, lower labor costs, and higher overall quality in electronic devices.

Overall, rigid-flex PCB assembly offers a wide range of benefits for electronic devices, including compact size, durability, reliability, improved signal integrity, reduced electromagnetic interference, and cost savings.

By choosing rigid-flex PCBs for their designs, engineers and designers can create innovative and high-performance electronic devices that meet the demands of today’s fast-paced and ever-changing technology landscape.

In conclusion, rigid-flex PCB assembly is a versatile and reliable solution for electronic devices that require both flexibility and durability.

By combining the best of both flexible and rigid PCB technologies, rigid-flex PCBs offer numerous benefits that can help improve the performance, reliability, and cost-effectiveness of electronic devices.

Whether used in medical devices, aerospace systems, automotive electronics, or consumer electronics, rigid-flex PCB assembly is a proven and effective solution for ensuring quality and durability in electronic devices.