Benefits of Rigid-Flex PCB Assembly

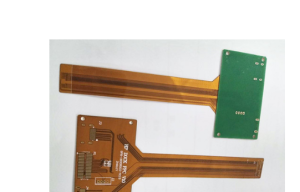

Rigid-flex PCB assembly offers a unique solution for applications that require a combination of rigid and flexible circuit boards.

This innovative technology allows for the integration of multiple PCBs into a single, compact unit, providing a more efficient and reliable solution for a wide range of electronic devices. In this article, we will explore the benefits of rigid-flex PCB assembly and how it can be customized to meet the specific needs of different applications.

One of the key benefits of rigid-flex PCB assembly is its ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible circuit boards into a single unit, designers can create more compact and lightweight products without sacrificing functionality. This is particularly important for applications where space is limited, such as in wearable devices, medical implants, and aerospace systems.

In addition to saving space, rigid-flex PCB assembly also offers improved reliability and durability compared to traditional PCBs.

The flexible sections of the board are designed to withstand bending and flexing without compromising the integrity of the circuitry, making them ideal for applications that require frequent movement or vibration.

This increased durability can help to extend the lifespan of electronic devices and reduce the need for costly repairs or replacements.

Another advantage of rigid-flex PCB assembly is its ability to simplify the manufacturing process.

By integrating multiple PCBs into a single unit, designers can reduce the number of components and connections required, streamlining the assembly process and reducing the risk of errors. This can help to lower production costs and improve time-to-market for new products, giving companies a competitive edge in today’s fast-paced electronics industry.

Customization is another key benefit of rigid-flex PCB assembly. Designers can tailor the layout and configuration of the boards to meet the specific requirements of different applications, allowing for greater flexibility and versatility in product design.

Whether it’s a complex medical device that requires precise positioning of sensors and electrodes, or a rugged industrial control system that needs to withstand harsh environmental conditions, rigid-flex PCB assembly can be customized to deliver the performance and reliability needed for each unique application.

Furthermore, rigid-flex PCB assembly offers improved signal integrity and EMI/RFI shielding compared to traditional PCBs.

The flexible sections of the board can be designed to minimize signal loss and interference, ensuring that electronic devices operate at peak performance.

This is particularly important for high-speed data transmission and sensitive electronic components, where even small disruptions can lead to malfunctions or data corruption.

Overall, rigid-flex PCB assembly provides a range of benefits for a variety of applications, from consumer electronics to industrial equipment.

By combining the advantages of rigid and flexible circuit boards, designers can create more compact, reliable, and customizable solutions that meet the unique requirements of each application.

Whether it’s reducing size and weight, improving durability and reliability, simplifying manufacturing processes, or enhancing signal integrity, rigid-flex PCB assembly offers a versatile and effective solution for today’s electronics industry.