Benefits of Rigid-Flex PCB Assembly

Rigid-flex PCB assembly has become increasingly popular in the electronics industry due to its numerous benefits and innovative design possibilities.

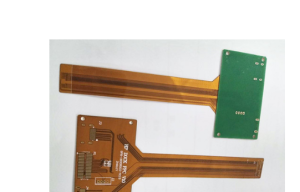

This type of PCB combines rigid and flexible circuitry into a single board, allowing for greater flexibility in design and improved reliability.

In this article, we will explore the benefits of rigid-flex PCB assembly and discuss some best practices and innovations in the field.

One of the key benefits of rigid-flex PCB assembly is its ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible circuitry into a single board, designers can create more compact and lightweight products without sacrificing functionality. This is especially important in industries such as aerospace, medical devices, and consumer electronics, where space and weight constraints are critical considerations.

Another advantage of rigid-flex PCB assembly is its improved reliability.

Traditional PCBs are prone to failure due to factors such as vibration, shock, and thermal stress. Rigid-flex PCBs, on the other hand, are more resistant to these environmental factors, resulting in a more reliable and durable product.

This is particularly important in applications where reliability is paramount, such as in automotive electronics and industrial control systems.

In addition to size, weight, and reliability benefits, rigid-flex PCB assembly also offers greater design flexibility.

Designers can create complex and innovative layouts that would be impossible with traditional PCBs.

This opens up new possibilities for product design and functionality, allowing for more creative and efficient solutions to engineering challenges.

To ensure the successful assembly of rigid-flex PCBs, it is important to follow best practices and utilize the latest innovations in the field. One key best practice is to work closely with experienced PCB manufacturers who have expertise in rigid-flex assembly.

These manufacturers can provide valuable guidance on design considerations, material selection, and manufacturing processes to ensure a successful outcome.

In terms of innovations, one of the most exciting developments in rigid-flex PCB assembly is the use of advanced materials such as flexible substrates and conductive inks.

These materials offer improved performance and reliability compared to traditional materials, allowing for more complex and reliable designs.

Additionally, advancements in manufacturing techniques such as laser drilling and 3D printing have made it easier to create intricate and precise rigid-flex PCBs.

Overall, rigid-flex PCB assembly offers a wide range of benefits for electronic designers and manufacturers.

From reduced size and weight to improved reliability and design flexibility, rigid-flex PCBs are revolutionizing the way electronic devices are built.

By following best practices and embracing the latest innovations in the field, designers can take full advantage of the benefits of rigid-flex PCB assembly and create cutting-edge products that push the boundaries of technology.