Benefits of Using Rigid Flex PCBs in Automotive Applications

Rigid flex PCBs, or printed circuit boards, have become increasingly popular in the automotive industry due to their numerous benefits and applications.

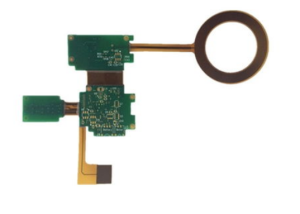

These innovative PCBs combine the flexibility of flexible circuits with the durability of rigid boards, making them ideal for a wide range of automotive applications.

One of the key benefits of using rigid flex PCBs in automotive applications is their ability to withstand harsh environmental conditions.

Vehicles are exposed to extreme temperatures, vibrations, and moisture, which can damage traditional PCBs.

Rigid flex PCBs, on the other hand, are designed to be more robust and reliable, making them well-suited for automotive use.

In addition to their durability, rigid flex PCBs offer significant space-saving advantages. In modern vehicles, space is at a premium, and traditional PCBs can take up valuable real estate. Rigid flex PCBs, with their compact design and ability to be folded or bent, allow for more efficient use of space in automotive applications. This can lead to lighter, more streamlined vehicles with improved performance.

Another benefit of using rigid flex PCBs in automotive applications is their ability to reduce assembly time and costs.

Traditional PCBs require multiple components and connections, which can be time-consuming and expensive to assemble.

Rigid flex PCBs, with their integrated design and fewer connections, simplify the assembly process and reduce the risk of errors.

This can result in faster production times and lower overall costs for automotive manufacturers.

Furthermore, rigid flex PCBs offer improved reliability and performance compared to traditional PCBs.

The flexible sections of the PCBs can absorb vibrations and shocks, reducing the risk of damage to the board and its components.

This can lead to longer-lasting, more reliable automotive systems that require less maintenance and repair.

One of the key applications of rigid flex PCBs in the automotive industry is in safety systems. These systems, such as airbags, anti-lock brakes,

and collision avoidance systems, require high levels of reliability and performance to ensure the safety of vehicle occupants.

Rigid flex PCBs are well-suited for these applications due to their durability, space-saving design, and ability to withstand harsh environmental conditions.

Another important application of rigid flex PCBs in the automotive industry is in infotainment systems.

Modern vehicles are equipped with a wide range of electronic features, including GPS navigation, entertainment systems, and connectivity options.

Rigid flex PCBs provide the flexibility and reliability needed to support these advanced technologies, ensuring a seamless and enjoyable driving experience for consumers.

In conclusion, rigid flex PCBs offer numerous benefits for automotive applications, including durability, space-saving design, reduced assembly time and costs, improved reliability, and performance. These innovative PCBs are well-suited for a wide range of automotive systems, from safety systems to infotainment systems, and are helping to drive innovation and advancement in the automotive industry. As vehicles continue to become more technologically advanced, rigid flex PCBs will play an increasingly important role in shaping the future of automotive design and performance.