Benefits of Using Rigid-Flex PCBs in Electronic Devices

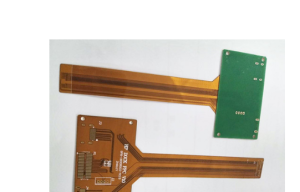

Flexible circuit technologies have revolutionized the way electronic devices are designed and manufactured. One of the most innovative advancements in this field is the development of rigid-flex PCBs, which combine the benefits of both rigid and flexible circuits into a single solution. These hybrid boards offer a wide range of advantages over traditional PCBs, making them an ideal choice for a variety of applications.

One of the key benefits of using rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices. By combining rigid and flexible sections into a single board, designers can create more compact and lightweight products without sacrificing functionality. This is particularly important in industries where space is at a premium, such as aerospace, medical devices, and wearable technology.

In addition to their compact size, rigid-flex PCBs also offer improved reliability and durability compared to traditional PCBs. The flexible sections of the board are designed to withstand bending and flexing without compromising the integrity of the circuitry. This makes rigid-flex PCBs ideal for applications where the board may be subjected to repeated bending or vibration, such as in automotive electronics or portable devices.

Another advantage of using rigid-flex PCBs is their ability to simplify the assembly process. By combining multiple PCBs into a single rigid-flex board, manufacturers can reduce the number of interconnects and solder joints, which can help to improve overall reliability and reduce the risk of assembly errors. This can also lead to cost savings in terms of materials and labor, making rigid-flex PCBs a cost-effective solution for many applications.

Furthermore, rigid-flex PCBs offer greater design flexibility compared to traditional PCBs. Designers can create complex, three-dimensional shapes and layouts that would be difficult or impossible to achieve with rigid boards alone. This opens up new possibilities for innovative product designs and can help to differentiate electronic devices in a competitive market.

In addition to their technical advantages, rigid-flex PCBs also offer environmental benefits. By reducing the overall size and weight of electronic devices, manufacturers can minimize the use of materials and energy required for production. This can help to reduce the carbon footprint of electronic products and contribute to a more sustainable manufacturing process.

Overall, the benefits of using rigid-flex PCBs in electronic devices are clear. From improved reliability and durability to reduced size and weight, these hybrid boards offer a wide range of advantages over traditional PCBs. With their ability to simplify assembly, increase design flexibility, and reduce environmental impact, rigid-flex PCBs are an ideal choice for a variety of applications in industries ranging from aerospace to consumer electronics. As technology continues to evolve, rigid-flex PCBs will likely play an increasingly important role in shaping the future of electronic devices.