Benefits of Rigid Flex Assembly in Electronics Manufacturing

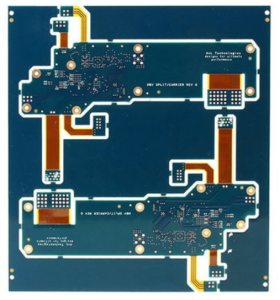

Rigid flex assembly is a critical process in electronics manufacturing that offers numerous benefits for companies looking to create high-quality, reliable products. By combining the flexibility of flexible circuits with the durability of rigid boards, rigid flex assembly allows for the creation of complex, compact designs that can withstand the rigors of everyday use.

One of the key benefits of rigid flex assembly is its ability to reduce the overall size and weight of electronic devices. By eliminating the need for bulky connectors and cables, rigid flex assemblies can help companies create sleek, compact products that are easier to transport and use. This can be especially important for industries such as aerospace, automotive, and medical devices, where space and weight constraints are critical considerations.

In addition to reducing size and weight, rigid flex assemblies can also improve the reliability and durability of electronic devices. By eliminating the need for multiple interconnects and solder joints, rigid flex assemblies can reduce the risk of mechanical failure and improve overall product performance. This can be especially important for applications where reliability is paramount, such as in military and aerospace systems.

Another key benefit of rigid flex assembly is its ability to simplify the manufacturing process. By combining multiple components into a single assembly, companies can reduce the number of steps required to build a product, saving time and reducing costs. This can be especially important for companies looking to streamline their production processes and improve efficiency.

Despite these benefits, there are several key considerations that companies must keep in mind when implementing rigid flex assembly. One of the most important considerations is the design of the rigid flex assembly itself. Companies must carefully consider factors such as the number of layers, the placement of components, and the routing of traces to ensure that the assembly meets the requirements of the final product.

In addition to design considerations, companies must also carefully select materials for their rigid flex assemblies. Choosing the right materials can have a significant impact on the performance and reliability of the final product. Companies must consider factors such as thermal stability, flexibility, and resistance to moisture and chemicals when selecting materials for their rigid flex assemblies.

Another key consideration for companies implementing rigid flex assembly is the manufacturing process itself. Companies must work closely with their manufacturing partners to ensure that the assembly process is carried out correctly and efficiently. This may involve conducting thorough testing and quality control measures to ensure that the final product meets the required specifications.

Overall, rigid flex assembly offers numerous benefits for companies looking to create high-quality, reliable electronic products. By combining the flexibility of flexible circuits with the durability of rigid boards, rigid flex assemblies can help companies reduce size and weight, improve reliability and durability, and simplify the manufacturing process. However, companies must carefully consider factors such as design, materials, and manufacturing processes to ensure the success of their rigid flex assembly projects.