Industrial IoT gateways are crucial components in the realm of Industrial Internet of Things (IIoT) applications, facilitating seamless communication between various machines, devices, and networks in industrial settings.

The reliability and durability of these gateways are paramount for uninterrupted operations and data transmission.

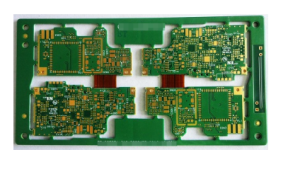

In this digital age where connectivity is key, high-reliability rigid-flex assemblies emerge as a cutting-edge solution for ensuring the robustness and efficiency of Industrial IoT gateways.

What are High-Reliability Rigid-Flex Assemblies?

High-reliability rigid-flex assemblies are advanced circuit board configurations that combine rigid and flexible substrates, providing a unique blend of structural integrity and adaptability.

These assemblies offer superior performance in challenging environments characterized by vibrations, shocks, temperature fluctuations, and limited space constraints, making them an ideal choice for industrial IoT gateway applications.

Benefits of High-Reliability Rigid-Flex Assemblies in IIoT Gateways

- Enhanced Durability:

High-reliability rigid-flex assemblies are designed to withstand harsh industrial environments, ensuring continuous operation of IIoT gateways even in demanding conditions.

Their robust construction minimizes the risk of damage due to mechanical stress and environmental factors, enhancing the overall durability of the system. - Space Efficiency:

The compact nature of rigid-flex assemblies allows for efficient utilization of space within IIoT gateway devices.

By integrating rigid and flexible areas on the same board, these assemblies enable designers to create streamlined and compact solutions without compromising on performance or reliability. - Reliable Signal Integrity:

Maintaining signal integrity is critical in industrial applications where data accuracy and reliability are paramount.

High-reliability rigid-flex assemblies offer excellent signal integrity, reducing electromagnetic interference and signal losses, thus ensuring seamless communication within IIoT networks. - Cost-Effectiveness:

While the initial investment in high-reliability rigid-flex assemblies may be higher compared to traditional PCBs, the long-term cost savings make them a cost-effective choice for IIoT gateway manufacturers.

The enhanced durability and reliability of these assemblies result in reduced maintenance and replacement costs over time.

Design Considerations for High-Reliability Rigid-Flex Assemblies

When incorporating high-reliability rigid-flex assemblies into Industrial IoT gateways, several key design considerations must be taken into account to maximize performance and reliability:

- Material Selection:

Choosing the right materials for rigid and flexible substrates is crucial in ensuring the longevity and performance of the assembly.

High-quality materials that offer excellent mechanical and thermal properties are essential for withstanding the rigors of industrial environments. - Routing and Layout:

Optimizing the routing and layout of rigid-flex assemblies is vital for minimizing signal interference, ensuring signal integrity, and maximizing space efficiency.

Careful planning and adherence to best practices in PCB design can help mitigate potential issues and optimize performance. - Connector Reliability:

Selecting reliable connectors that can withstand frequent mating cycles, shocks, and vibrations is essential for maintaining the integrity of the connection within the IIoT gateway.

Robust connectors that provide secure and stable connections are imperative for long-term reliability.

Conclusion

In conclusion, high-reliability rigid-flex assemblies offer a compelling solution for enhancing the durability, efficiency, and reliability of Industrial IoT gateways in demanding industrial environments.

By leveraging the unique benefits of rigid-flex technology, manufacturers can design resilient and high-performing IIoT gateways that facilitate seamless communication and data exchange in the era of Industry 4.0. Embracing the advancements in high-reliability rigid-flex assemblies is key to unlocking the full potential of Industrial IoT applications and ensuring the smooth operation of interconnected industrial systems.