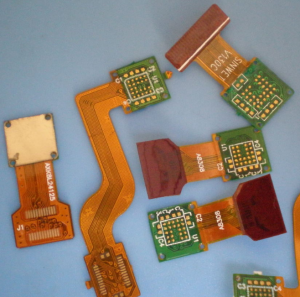

How to Reduce Rigid-Flex PCB Design Costs Without Sacrificing Quality

Reducing rigid-flex PCB design costs while maintaining high quality is an essential goal for many manufacturers in today’s competitive market.

Rigid-flex PCBs offer significant advantages, such as flexibility and durability, but their complex nature can lead to increased production costs.

Fortunately, there are several strategies and best practices that can help keep these costs in check without compromising on quality.

Understanding Rigid-Flex PCB Basics

Before diving into cost-reduction strategies, it’s vital to understand what rigid-flex PCBs are.

These boards combine the properties of rigid and flexible PCBs into a single, multi-layer structure.

They are used in applications requiring detailed layouts, like smartphones, medical devices, and aerospace technologies.

The unique design allows for significant space-saving and enhanced component connectivity, but this complexity can drive costs up.

Design Simplification

One of the most effective ways to reduce rigid-flex PCB design costs is to simplify the design itself.

The complexity of a PCB design often correlates directly with manufacturing costs. Here are several tactics for simplifying your designs:

- Minimize Layer Count: Simplifying your design to minimize layer count can significantly lower production costs.

This may require careful routing and judicious use of vias, but it can lead to substantial savings. - Standardize Components: Using standard components instead of custom parts can reduce costs.

Standard components are usually available in bulk, which lowers their prices and can reduce lead times. - Optimize Layout: A well-optimized layout not only enhances performance but also reduces the amount of copper needed, thus cutting costs.

Employ various software tools to assist in optimizing trace widths and placements.

DFM and DFA Considerations

Design for Manufacturing (DFM) and Design for Assembly (DFA) play crucial roles in controlling costs.

By considering manufacturing processes early in the design phase, you can avoid costly design iterations later on.

- Choose the Right Materials: Selecting the right materials for your application can impact both performance and cost.

Explore alternatives and request samples to test before finalizing your choices. - Collaborate with Manufacturers: Involve your PCB manufacturer in the design process.

Their insights can help you identify potential issues early, diverting costly mistakes later on. - Establish a Prototyping Process: Implementing a robust prototyping process allows for early detection of design flaws.

Catching issues at the prototype stage is significantly less expensive than during production.

Efficient Manufacturing Techniques

Many manufacturing techniques can help lower costs without sacrificing quality. Here are some to consider:

- Utilize Advanced Production Technologies: Technologies like laser cutting can improve precision and reduce material waste, leading to lower overall costs.

- Batch Production: Producing PCBs in larger batches can often yield economies of scale.

Discuss batch sizes with your manufacturer to find optimal quantities for production runs. - Quality Control Measures: Investing in quality control measures during manufacturing can prevent expensive rework and rejection of defective boards.

Employ automated optical inspection systems to catch defects early.

Supply Chain Management

Effective supply chain management is another critical strategy for reducing costs. Here are several ways to streamline your supply chain:

- Source Locally: Working with local suppliers can reduce shipping costs and lead times.

This can also allow for more responsive handling of any issues that arise. - Bulk Purchasing: Negotiating bulk purchase agreements for your materials can lead to significant savings. Just make sure to forecast accurately to avoid overstocking.

- Establish Long-Term Relationships: Developing long-term relationships with suppliers can yield benefits like reduced costs, better service, and greater flexibility.

Conclusion

Reducing rigid-flex PCB design costs without sacrificing quality is a multifaceted approach that requires attention to various aspects of the design, manufacturing, and supply chain processes.

By simplifying designs, incorporating DFM and DFA principles, utilizing efficient manufacturing techniques, and managing your supply chain effectively, you can achieve significant cost savings.

In today’s fast-paced electronics market, these strategies not only help in cutting costs but also enhance your product’s overall performance and reliability.

Embracing these practices will ensure your rigid-flex PCB designs are both economical and high-quality, keeping your projects on track and your bottom line healthy.