Rapid Prototyping: The production process allows for rapid prototyping, enabling faster development cycles for new smart devices

In the fast-paced world of electronics, the ability to quickly develop and test new ideas is critical to staying competitive.

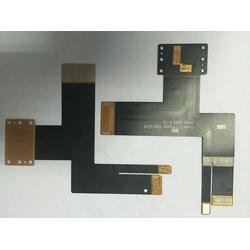

Rigid-flex printed circuit boards (PCBs) have become a cornerstone of rapid prototyping, enabling faster development cycles for new smart devices.

By combining the strengths of rigid and flexible circuits, rigid-flex PCBs streamline the prototyping process, allowing engineers to iterate designs, test functionality, and bring innovative products to market more efficiently.

One of the key advantages of rigid-flex PCBs in rapid prototyping is their ability to integrate complex circuitry into a single, compact design.

Traditional prototyping methods often require multiple rigid PCBs connected by wires or connectors, which can be time-consuming to assemble and test. Rigid-flex PCBs, on the other hand, combine rigid and flexible sections into a unified structure, eliminating the need for additional components and simplifying the design process. This integration allows engineers to quickly create functional prototypes that closely resemble the final product, reducing the time and effort required for testing and validation.

The flexibility of rigid-flex PCBs also enables designers to experiment with innovative form factors and configurations.

For example, wearable devices, foldable smartphones, and IoT sensors often require unique shapes and layouts that are difficult to achieve with traditional PCBs. Rigid-flex PCBs can be easily customized to fit these unconventional designs, allowing engineers to test new concepts and refine their ideas during the prototyping phase. This flexibility is particularly valuable in industries like consumer electronics and medical devices, where innovation and differentiation are key to success.

Another benefit of rigid-flex PCBs in rapid prototyping is their compatibility with advanced manufacturing techniques.

Technologies such as 3D printing, laser cutting, and automated assembly can be used to produce rigid-flex PCBs quickly and accurately, even in small quantities. This makes it possible to create prototypes in a matter of days or weeks, rather than months, accelerating the development cycle and allowing companies to respond more quickly to market demands.

The durability of rigid-flex PCBs also contributes to faster prototyping. Unlike traditional PCBs, which may require additional enclosures or reinforcements to withstand testing, rigid-flex PCBs are inherently robust and resistant to mechanical stress. This durability allows engineers to subject prototypes to rigorous testing without fear of damage, ensuring that the final product will be reliable and functional. For example, prototypes of automotive electronics or aerospace systems can be tested under extreme conditions, such as high temperatures or vibrations, to validate their performance.

Furthermore, the streamlined assembly process of rigid-flex PCBs reduces the risk of errors and rework during prototyping.

With fewer components to connect and assemble, the likelihood of mistakes is significantly lower, resulting in higher-quality prototypes and fewer delays.

This efficiency is particularly important in industries like IoT and wearable technology, where time-to-market is critical.

In conclusion, rigid-flex PCBs are a powerful tool for rapid prototyping, enabling faster development cycles and accelerating innovation in smart devices.

Their ability to integrate complex circuitry, support innovative designs, and withstand rigorous testing makes them an ideal choice for engineers and designers looking to bring new ideas to life. As the demand for smarter, more efficient electronics continues to grow, rigid-flex PCBs will remain a vital technology, driving the development of next-generation devices and shaping the future of the electronics industry.