Radiation-Hardened SiC-Integrated Rigid-Flex for Deep Space Avionics

Radiation-hardened SiC-integrated rigid-flex technology is revolutionizing deep space avionics systems with robust designs capable of withstanding the extreme conditions of space.

As we venture further into the cosmos, developing reliable electronics that can operate under high radiation environments becomes increasingly critical.

This technology not only improves functionality but also ensures the longevity and reliability of space missions.

Understanding the Importance of Radiation Hardening

Before delving into the specifics of SiC-integrated rigid-flex technology, it’s essential to understand the concept of radiation hardening.

In deep space, devices are exposed to cosmic rays, solar particles, and other forms of high-energy radiation that can disrupt electronic circuits and degrade materials.

Radiation hardening involves the design and manufacturing of systems and components to resist these harmful effects, ensuring they maintain performance without failure.

Silicon Carbide: The Material of Choice

At the heart of recent advancements is silicon carbide (SiC), a semiconductor that offers significant advantages over traditional materials.

This compound possesses unique electrical and thermal properties, making it highly resistant to radiation effects.

SiC allows for higher power capabilities, improved heat dissipation, and greater overall performance under harsh conditions.

In the context of avionics, integrating SiC with rigid-flex technology results in lighter, more efficient systems that can thrive in the demanding environments of space.

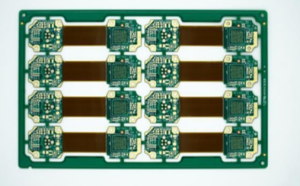

Rigid-Flex Technology Explained

Rigid-flex technology combines rigid printed circuit boards (PCBs) with flexible ones, providing mechanical flexibility without sacrificing structural integrity.

This integration is crucial in space environments where weight and space are always at a premium.

By using rigid-flex designs, engineers can create compact avionics that fit neatly into spacecraft, enhancing flexibility in layout and reducing the potential for failure.

The Synergy of SiC and Rigid-Flex in Deep Space Avionics

The integration of radiation-hardened SiC with rigid-flex technology offers substantial advantages for deep space avionics:

- Weight Reduction: Spacecraft are always looking to shave off excess weight.

The combined technology significantly reduces the number of components and wiring needed, thereby minimizing weight and optimizing space. - Improved Thermal Management: SiC’s superior thermal conductivity facilitates efficient heat dissipation. This is vital in avionics where temperature fluctuations can affect performance.

Rigid-flex designs allow for effective routing of thermal management solutions, enhancing the system’s overall thermal stability. - Increased Reliability: Systems exposed to radiation must maintain their integrity over extended periods. SiC’s robust nature, in concert with rigid-flex technology, promotes increased reliability in electronics, reducing the likelihood of failure due to radiation-induced damage.

- Enhanced Performance Capabilities: The combination leads to faster processing speeds and the ability to operate efficiently in various temperatures and conditions, paramount for deep space missions where delays are not an option.

Applications in Space Missions

As we look to the future, the potential applications for radiation-hardened SiC-integrated rigid-flex technology in deep space avionics are vast:

- Satellites and Probes: Missions to outer planets like Mars, Jupiter, and beyond require durable electronics that can withstand radiation while fulfilling complex operational mandates.

- Space Telescopes: These instruments often operate in highly energetic environments, making resilient avionics crucial for collecting data without interruption.

- Human Exploration Missions: As we prepare for potential manned missions to Mars and deeper into the solar system, engineers must ensure that human-piloted spacecraft possess systems that can endure both radiation exposure and the mechanical stresses of long-duration spaceflight.

Concluding Thoughts

The marriage of radiation-hardened SiC-integrated rigid-flex technology presents a significant leap forward in deep space avionics.

The evolution of this technology will not only meet the immediate challenges presented by radiation in space but will also pave the way for groundbreaking exploration and discovery.

As we push the boundaries of our technological capabilities, investing in these advanced systems is paramount for the success of future space missions.

It is essential now more than ever to embrace innovations that promote resilience and safety in our quest to explore the final frontier.