Exploring the Benefits of Flex Rigid PCBs in Modern Electronics

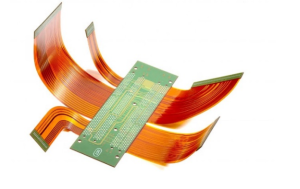

Flex rigid PCBs, or flexible rigid printed circuit boards, have revolutionized the world of electronics with their ability to push the boundaries of design and functionality. These innovative PCBs combine the flexibility of a flexible circuit with the durability of a rigid circuit, allowing for greater design freedom and improved performance in a wide range of electronic devices. In this article, we will explore the benefits of flex rigid PCBs in modern electronics and how advancements in their design are shaping the future of technology.

One of the key advantages of flex rigid PCBs is their ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, flex rigid PCBs enable manufacturers to create more compact and lightweight products without sacrificing performance. This is particularly important in industries such as aerospace, automotive, and medical devices, where space and weight constraints are critical considerations.

In addition to their compact size, flex rigid PCBs also offer improved reliability and durability compared to traditional rigid PCBs.

The flexible portions of the PCBs are less prone to mechanical stress and vibration, reducing the risk of component failure and extending the lifespan of the device. This makes flex rigid PCBs ideal for applications that require high reliability and long-term performance, such as military equipment and industrial machinery.

Furthermore, flex rigid PCBs allow for more complex and intricate designs that would be difficult or impossible to achieve with traditional rigid PCBs.

The flexibility of the circuit allows for three-dimensional routing, enabling designers to create compact layouts that maximize space efficiency and optimize signal integrity. This level of design flexibility is particularly valuable in high-speed and high-frequency applications, where signal integrity is critical to the performance of the device.

Another benefit of flex rigid PCBs is their cost-effectiveness in terms of assembly and maintenance.

The elimination of connectors and cables reduces the number of components that need to be assembled, simplifying the manufacturing process and reducing labor costs. Additionally, the improved reliability of flex rigid PCBs means that maintenance and repair costs are minimized, leading to lower overall lifecycle costs for electronic devices.

As technology continues to advance, so too do the capabilities of flex rigid PCBs. Recent advancements in materials and manufacturing processes have further improved the performance and reliability of these innovative PCBs, opening up new possibilities for their use in a wide range of applications. For example, the development of high-temperature materials has enabled flex rigid PCBs to withstand extreme operating conditions, making them suitable for use in harsh environments such as automotive engine compartments and industrial machinery.

Furthermore, advancements in additive manufacturing techniques have made it possible to create complex and customized flex rigid PCBs with unprecedented precision and speed. This has opened up new opportunities for designers to push the boundaries of what is possible in terms of electronic device design, leading to the development of more innovative and cutting-edge products.

In conclusion, flex rigid PCBs have revolutionized the world of electronics with their ability to push the boundaries of design and functionality.

Their compact size, improved reliability, design flexibility, and cost-effectiveness make them an ideal choice for a wide range of applications, from consumer electronics to aerospace and defense. With continued advancements in materials and manufacturing processes, the future looks bright for flex rigid PCBs as they continue to shape the future of technology.