Strategies for Minimizing Warpage in Rigid-Flex Circuits

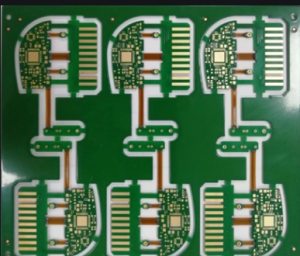

Rigid-flex circuits have become increasingly popular in modern electronics due to their ability to provide a compact and lightweight solution for complex electronic systems.

However, one of the challenges that engineers face when designing and manufacturing rigid-flex circuits is warpage.

Warpage can occur during the fabrication process or as a result of environmental factors, and it can lead to issues such as electrical failures, mechanical stress, and reliability problems.

In this article, we will discuss some strategies for minimizing warpage in rigid-flex circuits.

One of the key factors that contribute to warpage in rigid-flex circuits is the mismatch in coefficients of thermal expansion (CTE) between the different materials used in the construction of the circuit.

Rigid-flex circuits typically consist of a combination of rigid and flexible materials, such as FR-4, polyimide, and copper.

These materials have different CTE values, which can lead to stress and warpage when the circuit is exposed to temperature variations during the manufacturing process or in operation.

To minimize warpage due to CTE mismatch, engineers can take several steps during the design and fabrication of rigid-flex circuits.

One approach is to carefully select materials with similar CTE values for the rigid and flexible portions of the circuit. This can help to reduce the stress and strain that can lead to warpage.

Additionally, engineers can design the circuit layout in such a way that minimizes the differential expansion and contraction of materials during temperature cycling.

Another strategy for minimizing warpage in rigid-flex circuits is to optimize the lamination process during fabrication.

The lamination process involves bonding the different layers of the circuit together using heat and pressure.

If the lamination process is not carefully controlled, it can introduce stress and warpage into the circuit.

Engineers can work closely with their fabricators to develop optimized lamination processes that minimize warpage and ensure the reliability of the circuit.

In addition to material selection and lamination process optimization, engineers can also consider incorporating design features that help to mitigate warpage in rigid-flex circuits.

For example, adding stiffeners or support structures to the flexible portions of the circuit can help to reduce bending and warpage.

Engineers can also design the circuit layout to distribute stress evenly across the different materials, reducing the likelihood of warpage.

Environmental factors can also contribute to warpage in rigid-flex circuits.

Exposure to moisture, humidity, and temperature variations can cause the materials in the circuit to expand and contract, leading to stress and warpage.

To minimize the impact of environmental factors on warpage, engineers can consider using protective coatings or encapsulation materials that provide a barrier against moisture and other environmental hazards.

In conclusion, warpage is a common challenge in the design and manufacturing of rigid-flex circuits.

By carefully selecting materials, optimizing the lamination process, incorporating design features to mitigate warpage, and considering environmental factors, engineers can minimize the risk of warpage and ensure the reliability of their rigid-flex circuits. By following these strategies, engineers can overcome warpage challenges and create high-quality rigid-flex circuits for a wide range of electronic applications.