Maximizing Design Flexibility in Rigid Flex Manufacturing

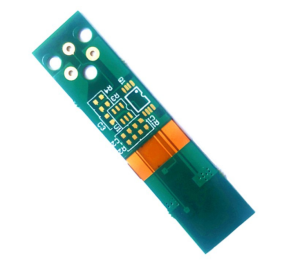

Rigid flex manufacturing is a complex process that involves combining rigid and flexible materials to create a single circuit board.

This innovative technology offers numerous benefits, such as reduced weight, improved reliability, and increased design flexibility.

However, like any manufacturing process, rigid flex manufacturing comes with its own set of challenges that can impact the quality and efficiency of the final product.

One common challenge in rigid flex manufacturing is ensuring that the design meets the specific requirements of the application.

Design flexibility is crucial in rigid flex manufacturing, as it allows engineers to create circuit boards that can fit into tight spaces or conform to unique shapes.

However, achieving this level of flexibility can be difficult, especially when working with rigid and flexible materials that have different properties.

To overcome this challenge, engineers must carefully consider the requirements of the application and work closely with the manufacturer to develop a design that meets those requirements.

This may involve making trade-offs between flexibility and rigidity, or finding creative solutions to accommodate both types of materials.

By maximizing design flexibility, engineers can ensure that the final product meets the needs of the application while maintaining the integrity of the circuit board.

Another common challenge in rigid flex manufacturing is ensuring that the materials are properly bonded together.

Rigid flex circuit boards are made up of multiple layers of rigid and flexible materials that are bonded together using adhesives or other bonding techniques.

If the materials are not properly bonded together, the circuit board may delaminate or fail prematurely, leading to costly rework or product recalls.

To overcome this challenge, manufacturers must carefully select the right materials and bonding techniques for the specific application.

This may involve conducting thorough testing and analysis to ensure that the materials are compatible and that the bonding process is effective.

By investing in high-quality materials and bonding techniques, manufacturers can ensure that the circuit boards are durable and reliable, even in harsh operating conditions.

In addition to design flexibility and material bonding, another common challenge in rigid flex manufacturing is ensuring that the circuit boards meet strict quality standards.

Rigid flex circuit boards are often used in high-reliability applications, such as aerospace, medical devices, and automotive electronics, where even minor defects can have serious consequences.

To overcome this challenge, manufacturers must implement rigorous quality control processes throughout the manufacturing process.

This may involve conducting thorough inspections and testing at each stage of production, as well as implementing corrective actions to address any issues that arise.

By prioritizing quality and reliability, manufacturers can ensure that the final product meets the highest standards and exceeds customer expectations.

In conclusion, rigid flex manufacturing offers numerous benefits, but it also comes with its own set of challenges.

By maximizing design flexibility, ensuring proper material bonding, and prioritizing quality control, manufacturers can overcome these challenges and

create high-quality, reliable circuit boards that meet the specific requirements of the application. With careful planning and attention to detail, engineers can

successfully navigate the complexities of rigid flex manufacturing and deliver innovative solutions that push the boundaries of technology.