Strategies for Overcoming Challenges in Rigid-Flex PCB Assembly and Testing

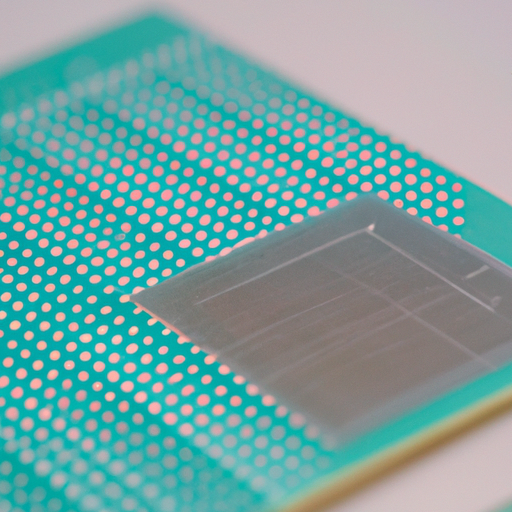

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their ability to reduce space and weight in electronic devices.

However, the assembly and testing of rigid-flex PCBs present unique challenges that require careful consideration and planning to ensure successful production.

One of the main challenges in rigid-flex PCB assembly is the complexity of the design.

Rigid-flex PCBs consist of both rigid and flexible sections, which require different assembly techniques and materials.

This complexity can lead to issues such as misalignment of components, poor solder joints, and electrical shorts.

To overcome these challenges, it is essential to work closely with the PCB manufacturer to ensure that the design is optimized for assembly and testing.

Another challenge in rigid-flex PCB assembly is the handling of flexible materials.

Flex materials are more delicate and prone to damage compared to rigid materials, making them more challenging to work with during assembly.

To address this challenge, it is important to use specialized tools and equipment designed for handling flexible materials,

as well as implementing proper training and procedures for assembly operators.

In addition to assembly challenges, testing rigid-flex PCBs can also be a complex process.

Traditional testing methods may not be suitable for rigid-flex PCBs due to their unique design and construction.

To overcome this challenge, it is important to develop customized testing procedures that take into account the specific requirements of rigid-flex PCBs.

This may involve using specialized test fixtures, implementing automated testing processes, and conducting thorough electrical and mechanical testing to ensure the reliability of the PCB.

Furthermore, the integration of rigid and flexible sections in a single PCB can lead to challenges in signal integrity and reliability.

The transition between rigid and flexible sections can introduce impedance mismatches, signal distortion, and mechanical stress, which can impact the performance and longevity of the PCB.

To address these challenges, it is important to carefully design the transition areas between rigid and flexible sections,

as well as conduct thorough signal integrity analysis and testing to ensure that the PCB meets the required specifications.

Overall, overcoming challenges in rigid-flex PCB assembly and testing requires a combination of careful design, specialized tools and equipment, customized testing procedures, and thorough analysis and testing.

By working closely with the PCB manufacturer and implementing best practices for assembly and testing, electronics manufacturers can ensure the successful production of high-quality rigid-flex PCBs that meet the demands of modern electronic devices.