Strategies for Improving Yield Rates in Rigid-Flex Assembly

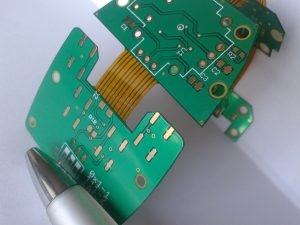

Rigid-flex assembly technology has become increasingly popular in the electronics industry due to its ability to reduce space requirements, improve reliability, and enhance overall product performance.

However, this innovative technology also presents unique challenges that manufacturers must overcome to achieve optimal yield rates and ensure the quality of their products.

One of the key challenges in rigid-flex assembly is the complexity of the process itself.

Unlike traditional PCB assembly, rigid-flex assembly involves the integration of rigid and flexible substrates, which requires specialized equipment and expertise.

As a result, manufacturers may encounter issues such as misalignment, delamination, and solder joint failures during the assembly process.

To address these challenges, manufacturers can implement a number of strategies to improve yield rates and ensure the quality of their rigid-flex assemblies.

One of the most important steps is to carefully design the layout of the rigid-flex PCB to minimize stress on the flexible substrates and ensure proper alignment of the rigid and flexible sections.

This can help prevent issues such as cracking and delamination, which can lead to costly rework and scrap.

In addition to proper design, manufacturers should also pay close attention to the selection of materials and components for their rigid-flex assemblies.

Using high-quality materials that are compatible with the specific requirements of rigid-flex assembly can help prevent issues such as solder joint failures and ensure the reliability of the final product.

It is also important to work closely with suppliers to ensure that all materials meet the necessary specifications and standards for rigid-flex assembly.

Another key factor in improving yield rates in rigid-flex assembly is the implementation of robust process controls and quality assurance measures.

This includes conducting thorough inspections and testing at each stage of the assembly process to identify and address any issues before they can impact the final product.

Manufacturers should also invest in training and certification programs for their assembly technicians to ensure that they have the necessary skills and knowledge to perform their jobs effectively.

Furthermore, manufacturers can leverage advanced technologies such as automated optical inspection (AOI) and X-ray inspection to detect defects and anomalies in their rigid-flex assemblies.

These technologies can help identify issues such as solder joint defects, misalignments, and component placement errors that may not be visible to the naked eye.

By implementing these technologies, manufacturers can improve the overall quality of their rigid-flex assemblies and reduce the risk of costly rework and scrap.

In conclusion, overcoming the challenges in rigid-flex assembly technology requires a combination of careful design, material selection, process controls, and quality assurance measures.

By implementing these strategies and best practices, manufacturers can improve yield rates, reduce defects, and ensure the reliability of their rigid-flex assemblies.

With the right approach and attention to detail, manufacturers can successfully navigate the complexities of rigid-flex assembly and deliver high-quality products to their customers.