Benefits of Rigid Flex PCB Integration

Rigid flex PCB integration offers a multitude of benefits for electronic devices, making them more reliable, durable, and efficient.

By combining the flexibility of flexible PCBs with the rigidity of traditional PCBs, manufacturers can optimize functionality in a variety of applications.

In this article, we will explore the advantages of integrating rigid flex PCBs into electronic devices.

One of the key benefits of rigid flex PCB integration is improved reliability.

Traditional PCBs are prone to failure due to factors such as vibration, shock, and thermal expansion.

By incorporating flexible sections into the design, rigid flex PCBs can better withstand these environmental stresses, resulting in a more reliable product.

This increased reliability is crucial for applications where downtime is not an option, such as medical devices, aerospace systems, and automotive electronics.

In addition to improved reliability, rigid flex PCB integration also offers enhanced durability.

Flexible PCBs are less susceptible to damage from bending and twisting, making them ideal for applications that require frequent movement or flexing.

By combining flexible and rigid sections, manufacturers can create a PCB that can withstand the rigors of everyday use without compromising performance. This durability is especially important for devices that are exposed to harsh environments or extreme conditions.

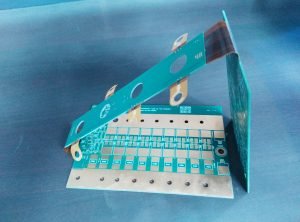

Another advantage of rigid flex PCB integration is increased design flexibility.

Traditional PCBs are limited in terms of shape and size, making it challenging to fit them into compact or irregularly shaped devices.

By incorporating flexible sections into the design, manufacturers can create PCBs that can be bent, folded, or twisted to fit the specific requirements of the device. This flexibility allows for more creative and innovative designs, leading to smaller, lighter, and more streamlined products.

Furthermore, rigid flex PCB integration can improve signal integrity and reduce electromagnetic interference.

Flexible PCBs have lower signal loss and crosstalk compared to traditional PCBs, resulting in better performance and reliability.

By integrating flexible sections into the design, manufacturers can minimize signal distortion and interference, leading to improved overall functionality.

This is particularly important for high-speed and high-frequency applications where signal integrity is critical.

Additionally, rigid flex PCB integration can streamline the manufacturing process and reduce assembly costs.

By combining multiple PCBs into a single rigid flex design, manufacturers can simplify the assembly process and reduce the number of components needed. This not only saves time and labor but also reduces the risk of errors and defects during assembly. Furthermore, the compact nature of rigid flex PCBs can lead to smaller and more cost-effective devices, making them an attractive option for manufacturers looking to optimize functionality while minimizing production costs.

In conclusion, integrating rigid flex PCBs into electronic devices offers a wide range of benefits, including improved reliability, durability, design flexibility, signal integrity, and cost-effectiveness. By combining the flexibility of flexible PCBs with the rigidity of traditional PCBs, manufacturers can create products that are more reliable, efficient, and innovative. As technology continues to advance, rigid flex PCB integration will play an increasingly important role in optimizing functionality in a variety of applications.