Multilayer Capabilities: Rigid flex PCBs can support multilayer designs, allowing for complex

The demand for smarter, smaller, and more efficient electronic devices has driven the need for advanced printed circuit board (PCB) technologies.

Among these, rigid-flex PCBs have emerged as a game-changer, particularly due to their ability to support multilayer designs.

This capability allows for the integration of complex circuitry within a single board, making rigid-flex PCBs an ideal solution for modern electronics that require high performance in compact form factors.

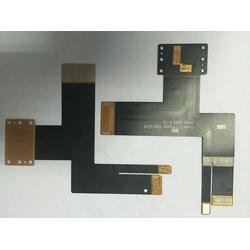

Rigid-flex PCBs combine the best of both rigid and flexible PCB technologies.

The rigid sections provide structural stability and support for mounting components, while the flexible sections enable the board to bend and fit into unconventional shapes. When multilayer capabilities are added to this mix, the result is a highly versatile PCB that can accommodate intricate circuit designs without compromising on space or reliability.

One of the key advantages of multilayer rigid-flex PCBs is their ability to support high-density interconnects (HDIs).

As electronic devices become more advanced, the number of components and connections required increases significantly.

Multilayer designs allow for the stacking of multiple conductive layers, separated by insulating materials, within a single board.

This not only saves space but also reduces the need for external wiring, minimizing the risk of signal interference and improving overall performance.

The multilayer structure also enhances signal integrity, which is critical for high-speed and high-frequency applications.

By carefully designing the layer stackup, engineers can optimize signal paths, reduce electromagnetic interference (EMI), and ensure efficient power distribution. This is particularly important in applications such as smartphones, wearable devices, and medical equipment, where reliability and precision are paramount.

Another benefit of multilayer rigid-flex PCBs is their ability to integrate complex functionalities into a single unit.

For example, a single rigid-flex PCB can combine power management, signal processing, and communication modules, eliminating the need for multiple boards and connectors. This not only simplifies the assembly process but also reduces the overall weight and size of the device.

Designing multilayer rigid-flex PCBs requires advanced tools and expertise.

Engineers must consider factors such as material selection, layer arrangement, and thermal management to ensure optimal performance.

Modern design software and simulation tools play a crucial role in this process, enabling designers to visualize and test their designs before manufacturing.

In conclusion, the multilayer capabilities of rigid-flex PCBs have revolutionized the way complex circuitry is implemented in modern electronics.

By enabling high-density interconnects, improving signal integrity, and integrating multiple functionalities into a single board, rigid-flex PCBs are paving the way for smaller, smarter, and more efficient devices. As technology continues to evolve, the importance of multilayer rigid-flex PCBs will only grow, solidifying their position as a cornerstone of advanced electronic design.