Miniaturized Rigid-Flex Assemblies for Compact AR/VR Headsets

Miniaturized rigid-flex assemblies revolutionize the design and performance of compact augmented reality (AR) and virtual reality (VR) headsets.

These advanced components integrate both rigid and flexible circuit technologies, allowing manufacturers to create sleek, lightweight devices that deliver powerful performance without sacrificing functionality.

As the demand for more compact and versatile AR/VR headsets increases, understanding the advantages of these innovative assemblies becomes essential for both developers and consumers.

The Evolution of AR/VR Technology

The increasing integration of AR and VR technologies into various sectors—ranging from gaming and education to healthcare and industrial applications—has sparked significant interest in optimizing headset designs. Manufacturers are striving for smaller, more efficient systems that enhance user experience while maintaining high-performance standards.

Miniaturized rigid-flex assemblies play a critical role in achieving these goals by enabling more compact designs with intricate circuit layouts.

What Are Miniaturized Rigid-Flex Assemblies?

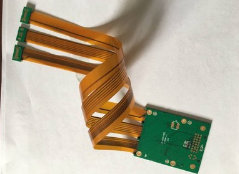

Miniaturized rigid-flex assemblies combine the benefits of rigid and flexible printed circuits.

A rigid-flex circuit board features sections that are both rigid and flexible, which can be bent and folded to fit into constrained spaces.

This flexibility allows designers to arrange components in a way that optimizes space utilization while ensuring electrical connections are strong and reliable.

These assemblies typically include a layered structure made from various materials such as polyimide and adhesive.

This design not only facilitates intricate pathways for electrical signals but also enables integration with other structures, including sensors and displays, essential for AR/VR headsets.

Benefits of Using Rigid-Flex Assemblies in Headsets

- Space Efficiency: One of the primary benefits of miniaturized rigid-flex assemblies is their ability to save space.

By incorporating both rigid and flexible areas, designers can place components closely together, allowing for a more compact overall design.

This is particularly crucial in the crowded environment of AR/VR headsets, where every millimeter counts. - Improved Durability: Rigid-flex assemblies are designed to withstand the wear and tear associated with daily use.

The flexible portions can resist stress and movement without breaking or losing connections, which enhances the longevity of AR/VR devices. - Enhanced Performance: The integration of advanced circuits and sensors into a miniaturized assembly allows for improved performance.

This can lead to better graphics, faster processing times, and an overall more immersive user experience. - Weight Reduction: Traditional circuit boards often require additional enclosures, which can add weight to the headset.

By combining rigid and flex technology, manufacturers can eliminate unnecessary materials, resulting in lighter devices that are easier for users to wear for extended periods.

Applications in AR/VR Devices

In the realm of AR and VR, miniaturized rigid-flex assemblies can be applied in several critical areas:

- Display Connectivity: These assemblies facilitate connections between the headset displays and processors, ensuring high-quality images with lower latency.

- Sensor Integration: Sensors for motion tracking, eye tracking, and environmental interaction can be seamlessly integrated into the headset’s structure, allowing for more responsive and immersive experiences.

- Power Supply Management: Efficient routing of power through rigid-flex designs minimizes energy loss and improves overall battery life in AR/VR headsets.

Challenges and Considerations

While the advantages of miniaturized rigid-flex assemblies are substantial, there are also challenges to consider.

Manufacturing these complex structures can be more demanding than producing traditional PCB designs.

Precision is crucial, and any errors during production can lead to costly rework or failures in the final product.

Moreover, the initial costs associated with developing custom rigid-flex solutions can be higher.

However, many manufacturers find that the long-term benefits outweigh these upfront expenses, especially as consumer demand for compact and high-performing devices grows.

Future Trends in AR/VR Headset Design

As technology continues to advance, the potential applications of miniaturized rigid-flex assemblies will expand.

Future developments may include even thinner designs, improved materials that enhance flexibility and durability, and advanced manufacturing techniques to lower costs.

This evolution will likely open the door to new features and capabilities in AR/VR headsets, making them more appealing to a broader audience.

Conclusion

Miniaturized rigid-flex assemblies represent a significant evolution in the design of compact AR and VR headsets.

By marrying the strengths of rigid and flexible circuit technologies, manufacturers can produce devices that are not only space-efficient but also durable and high-performing.

As the demand for immersive technologies continues to grow, the adoption of rigid-flex assemblies will play a pivotal role in shaping the future of AR and VR experiences.