In the realm of medical IoT devices and diagnostics, the demand for precision rigid-flex assemblies is at an all-time high.

These assemblies play a crucial role in powering the next generation of medical implants and diagnostic tools, offering a combination of flexibility and durability that is essential for the seamless integration of technology with the human body. With the advancements in technology and materials, precision rigid-flex assemblies are setting new standards in terms of reliability and performance in the medical field.

Evolution of Medical IoT Implants and Diagnostics

The evolution of medical IoT implants and diagnostics has revolutionized the way healthcare is delivered.

These devices are designed to collect, monitor, and transmit crucial data in real-time, providing healthcare providers with valuable insights into a patient’s condition.

However, the success of these technologies heavily relies on the reliability and precision of the components used in their construction, particularly the rigid-flex assemblies that form the backbone of these devices.

The Role of Precision Rigid-Flex Assemblies

Precision rigid-flex assemblies are at the heart of medical IoT implants and diagnostics.

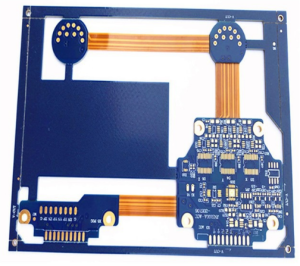

These assemblies combine rigid and flexible circuit boards into a single unit, offering the best of both worlds in terms of performance and reliability.

The rigid sections provide stability and support for components, while the flexible sections allow for complex 3D configurations and seamless integration into small spaces within the body.

This dynamic combination enables the development of compact, lightweight, and highly functional medical devices that can withstand the challenges of the human body’s internal environment.

Key Considerations in Designing Rigid-Flex Assemblies for Medical Use

When designing rigid-flex assemblies for medical IoT implants and diagnostics, several key considerations come into play.

The materials used must be biocompatible to ensure they do not cause any harm or adverse reactions when implanted inside the body.

Additionally, the assemblies must be durable enough to withstand the rigors of daily use and the body’s natural movements.

Moreover, precise manufacturing processes are essential to ensure the highest level of accuracy and reliability in these critical components.

Advantages of Precision Rigid-Flex Assemblies in Medical Applications

The advantages of precision rigid-flex assemblies in medical applications are manifold.

These assemblies offer a compact and lightweight solution for integrating complex electronics into small form factors, making them ideal for implantable devices such as pacemakers, neurostimulators, and drug delivery systems. Furthermore, their flexible nature allows for customizable designs that can conform to the unique shapes and contours of the human body, enabling comfortable and discreet placement of medical devices.

Challenges and Innovations in Rigid-Flex Assembly Technology

While precision rigid-flex assemblies have revolutionized the field of medical IoT implants and diagnostics, they also present unique challenges.

Ensuring signal integrity, thermal management, and reliability in harsh physiological environments are some of the key challenges that engineers and designers face when developing these assemblies.

However, ongoing innovations in materials, manufacturing techniques, and design processes are paving the way for overcoming these challenges and enhancing the performance and longevity of rigid-flex assemblies in medical applications.

Conclusion

Precision rigid-flex assemblies are instrumental in advancing the capabilities of medical IoT implants and diagnostics, pushing the boundaries of what is possible in the healthcare industry.

By combining flexibility, durability, and reliability, these assemblies are powering the development of cutting-edge medical devices that are revolutionizing patient care and treatment outcomes.

As technology continues to evolve, the role of precision rigid-flex assemblies will only grow in importance, solidifying their position as indispensable components in the future of healthcare innovation.