Benefits of Using Rigid Flex PCBs for Space Optimization

In the world of electronics, space optimization is a critical factor in the design and manufacturing process.

With the constant demand for smaller, more compact devices, engineers are constantly looking for ways to maximize space and efficiency without compromising on performance. One solution that has gained popularity in recent years is the use of rigid flex PCBs.

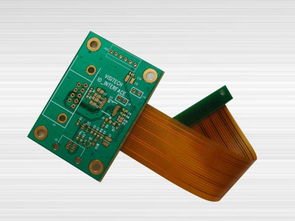

Rigid flex PCBs combine the best of both rigid and flexible circuit boards, offering a unique solution for space-constrained applications.

By integrating rigid and flexible sections into a single board, designers can achieve a higher level of flexibility in their designs while also reducing the overall size of the PCB. This allows for more compact and lightweight devices without sacrificing functionality.

One of the key benefits of using rigid flex PCBs for space optimization is the ability to reduce the number of interconnects required in a design.

Traditional PCBs often require multiple connectors and cables to connect different components, which can take up valuable space and add complexity to the design. With rigid flex PCBs, designers can eliminate the need for many of these interconnects by integrating them directly into the board itself.

This not only saves space but also improves reliability by reducing the number of potential points of failure.

Another advantage of using rigid flex PCBs for space optimization is the ability to design more complex and compact layouts.

The flexibility of the flexible sections allows for greater freedom in routing traces and placing components, enabling designers to create more efficient and streamlined designs. This can be particularly beneficial in applications where space is limited, such as wearable devices, medical implants, and aerospace systems.

In addition to space optimization, rigid flex PCBs also offer other benefits that can help improve the overall efficiency of a design.

For example, the combination of rigid and flexible sections can help reduce the overall weight of a device, making it more portable and easier to handle.

This can be especially important in applications where weight is a critical factor, such as in aerospace or automotive systems.

Furthermore, rigid flex PCBs can also help improve thermal management in a design.

The flexibility of the flexible sections allows for better heat dissipation, which can help prevent overheating and improve the overall reliability of the device.

This can be particularly important in high-power applications where heat generation is a concern.

Overall, the use of rigid flex PCBs for space optimization offers a range of benefits that can help designers create more compact, efficient, and reliable electronic devices. By combining the best of both rigid and flexible circuit boards, engineers can achieve a higher level of flexibility in their designs while also reducing the overall size of the PCB. This can lead to more innovative and streamlined products that meet the demands of today’s fast-paced and ever-changing market.