Benefits of Using Flex Rigid PCB Technology in Business Applications

In today’s fast-paced business world, efficiency is key to staying competitive and meeting customer demands.

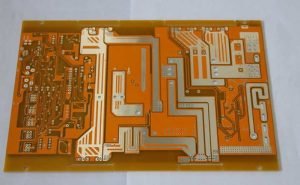

One way that businesses can maximize efficiency is by utilizing flex rigid PCB technology in their applications.

Flex rigid PCBs offer a number of benefits that can help businesses streamline their operations and improve their bottom line.

One of the main advantages of using flex rigid PCB technology in business applications is the flexibility it provides.

Flex rigid PCBs are designed to bend and twist, allowing them to fit into tight spaces and conform to the shape of the device they are being used in.

This flexibility makes them ideal for use in compact electronic devices, where space is at a premium. By using flex rigid PCBs, businesses can design smaller, more compact devices that are easier to transport and install.

Another benefit of using flex rigid PCB technology in business applications is the durability it offers.

Flex rigid PCBs are made from high-quality materials that are designed to withstand harsh environmental conditions,

such as extreme temperatures, moisture, and vibration. This durability makes them ideal for use in industrial applications, where reliability is crucial.

By using flex rigid PCBs, businesses can reduce the risk of equipment failure and costly downtime, leading to increased productivity and profitability.

In addition to their flexibility and durability, flex rigid PCBs also offer improved signal integrity.

The design of flex rigid PCBs allows for shorter signal paths, which reduces the risk of signal interference and improves overall performance.

This is especially important in high-speed applications, where even small disruptions in signal quality can have a significant impact on performance.

By using flex rigid PCBs, businesses can ensure that their devices operate at peak efficiency, leading to improved customer satisfaction and a competitive edge in the market.

Furthermore, flex rigid PCB technology can also help businesses reduce their overall production costs.

Flex rigid PCBs are designed to be lightweight and compact, which can lead to savings in materials and shipping costs.

Additionally, the flexibility of flex rigid PCBs allows for more efficient assembly processes, reducing labor costs and increasing production throughput.

By using flex rigid PCBs, businesses can streamline their manufacturing processes and improve their bottom line.

Overall, the benefits of using flex rigid PCB technology in business applications are clear.

From increased flexibility and durability to improved signal integrity and reduced production costs, flex rigid PCBs offer a number of

advantages that can help businesses maximize efficiency and stay ahead of the competition. By incorporating flex rigid PCB technology into

their applications, businesses can improve their operations, reduce costs, and deliver better products to their customers. In today’s fast-paced business world, flex rigid PCB technology is a valuable tool for businesses looking to stay competitive and drive success.