Benefits of Using Different Materials in Rigid-Flexible PCBs

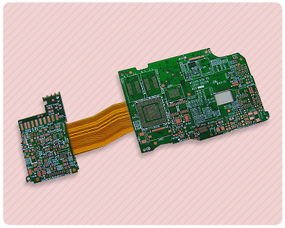

Rigid-flex PCBs are becoming increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs.

These boards are made up of both rigid and flexible materials, allowing for greater design flexibility and reliability. One of the key factors that contribute to the success of rigid-flex PCBs is the materials used in their construction.

The materials used in rigid-flex PCBs play a crucial role in determining the performance and reliability of the final product.

By carefully selecting the right materials, manufacturers can ensure that the PCB meets the specific requirements of the application.

Some of the common materials used in rigid-flex PCBs include FR-4, polyimide, and copper.

FR-4 is a popular choice for the rigid portions of rigid-flex PCBs due to its excellent electrical properties and mechanical strength.

This material is widely used in the electronics industry for its high thermal resistance and low moisture absorption.

FR-4 is also cost-effective, making it an attractive option for manufacturers looking to produce rigid-flex PCBs at a reasonable price.

Polyimide is another commonly used material in rigid-flex PCBs, particularly for the flexible portions of the board.

Polyimide is known for its high temperature resistance, flexibility, and excellent dielectric properties. These characteristics make polyimide an ideal choice for applications that require a high degree of flexibility, such as wearable devices and aerospace applications.

Copper is used in rigid-flex PCBs for its excellent conductivity and thermal properties.

Copper is typically used as the conductive material in the PCB, providing a reliable connection between components.

Copper is also highly resistant to corrosion, making it a durable choice for rigid-flex PCBs that are exposed to harsh environments.

By using a combination of these materials, manufacturers can create rigid-flex PCBs that offer a range of benefits.

One of the key advantages of using different materials in rigid-flex PCBs is the ability to tailor the board to meet specific design requirements.

For example, by using polyimide for the flexible portions of the board, manufacturers can create PCBs that can bend and flex without compromising performance.

Another benefit of using different materials in rigid-flex PCBs is improved reliability.

By selecting materials with the right properties, manufacturers can ensure that the PCB will perform reliably over its lifetime.

For example, using FR-4 for the rigid portions of the board can help to prevent warping and cracking, while using copper for the conductive traces can ensure a reliable connection between components.

In conclusion, the materials used in rigid-flex PCBs play a critical role in determining the performance and reliability of the final product.

By carefully selecting the right materials, manufacturers can create PCBs that offer a range of benefits, including design flexibility, reliability, and durability. With the increasing demand for flexible and reliable electronics, rigid-flex PCBs are likely to become even more prevalent in the industry, making it essential for manufacturers to understand the importance of materials selection in PCB design.