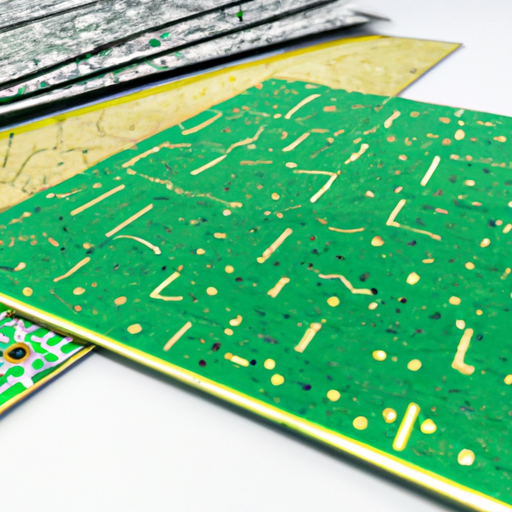

Benefits of Using Different Materials in Rigid Flex PCB Manufacturing

Rigid flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs.

These boards are made up of a combination of rigid and flexible materials, allowing for greater design flexibility and reliability.

One of the key factors that contribute to the success of rigid flex PCBs is the materials and substrates used in their manufacturing.

When it comes to rigid flex PCB manufacturing, the choice of materials plays a crucial role in determining the performance and reliability of the final product. Different materials offer different benefits, and selecting the right combination can significantly impact the overall quality of the PCB.

Some of the most commonly used materials in rigid flex PCB manufacturing include FR-4, polyimide, and copper.

FR-4 is a popular choice for rigid portions of rigid flex PCBs due to its excellent electrical properties, mechanical strength, and cost-effectiveness.

This material is widely used in the electronics industry and is known for its high thermal resistance and dimensional stability.

FR-4 is also easy to work with, making it a preferred choice for rigid PCBs that require complex designs and tight tolerances.

Polyimide, on the other hand, is commonly used for the flexible portions of rigid flex PCBs.

This material offers excellent flexibility, high temperature resistance, and good chemical resistance, making it ideal for applications that require bending and flexing.

Polyimide is also lightweight and has low moisture absorption, making it a reliable choice for flexible PCBs that need to withstand harsh environmental conditions.

Copper is another essential material in rigid flex PCB manufacturing, as it is used for the conductive traces that connect the different layers of the PCB.

Copper is known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance, making it an ideal choice for high-performance PCBs. Copper is also easy to work with and can be easily etched to create intricate circuit patterns.

By using a combination of these materials, manufacturers can create rigid flex PCBs that offer the best of both worlds – the reliability and stability of rigid PCBs, combined with the flexibility and versatility of flexible PCBs.

This allows for greater design freedom, improved performance, and increased durability, making rigid flex PCBs an attractive option for a wide range of applications.

In conclusion, the choice of materials and substrates used in rigid flex PCB manufacturing plays a crucial role in determining the performance and reliability of the final product.

By selecting the right combination of materials, manufacturers can create PCBs that offer the best of both rigid and flexible designs, providing greater design flexibility, improved performance, and increased durability.

With the right materials, rigid flex PCBs can meet the demanding requirements of modern electronics applications and continue to drive innovation in the industry.