Benefits of Low-Cost Bio-Based Polymers in Sustainable Rigid-Flex Electronics

In recent years, there has been a growing emphasis on sustainability in the electronics industry.

As consumers become more aware of the environmental impact of electronic devices, manufacturers are under increasing pressure to develop more sustainable products. One area where significant progress has been made is in the development of low-cost bio-based polymers for use in rigid-flex electronics.

Bio-based polymers are derived from renewable resources such as plants, algae, or bacteria, making them a more environmentally friendly alternative to traditional petroleum-based plastics. These materials offer a range of benefits, including reduced carbon footprint, biodegradability, and lower toxicity.

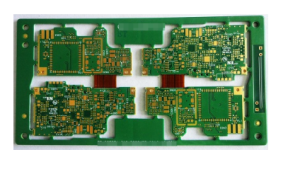

In the context of rigid-flex electronics, bio-based polymers have the potential to revolutionize the way electronic devices are designed and manufactured.

One of the key benefits of using low-cost bio-based polymers in rigid-flex electronics is their environmental impact.

Traditional plastics are derived from fossil fuels, which are non-renewable resources that contribute to greenhouse gas emissions and environmental degradation.

In contrast, bio-based polymers are made from renewable resources that can be sustainably harvested, reducing the carbon footprint of electronic devices.

Furthermore, bio-based polymers are biodegradable, meaning that they can be broken down by natural processes at the end of their lifecycle.

This is in stark contrast to traditional plastics, which can take hundreds of years to decompose in landfills.

By using bio-based polymers in rigid-flex electronics, manufacturers can reduce the amount of plastic waste that ends up in the environment, contributing to a more sustainable future.

In addition to their environmental benefits, low-cost bio-based polymers offer practical advantages for the design and manufacturing of rigid-flex electronics.

These materials are lightweight, flexible, and durable, making them ideal for use in electronic devices that require a high degree of flexibility and reliability.

Bio-based polymers can be easily molded into complex shapes, allowing for the creation of innovative designs that would be difficult or impossible to achieve with traditional plastics.

Furthermore, bio-based polymers have lower toxicity than traditional plastics, making them safer for both consumers and workers in the electronics industry.

Many traditional plastics contain harmful chemicals such as phthalates and bisphenol A, which have been linked to a range of health problems.

By using bio-based polymers in rigid-flex electronics, manufacturers can reduce the risk of exposure to these toxic substances, creating a safer working environment for employees and a healthier product for consumers.

Overall, the development of low-cost bio-based polymers for use in rigid-flex electronics represents a significant breakthrough in material innovation.

These materials offer a range of benefits, from reduced environmental impact to improved design flexibility and safety. As the electronics industry continues to evolve, the use of bio-based polymers is likely to become increasingly common, leading to a more sustainable and environmentally friendly future for electronic devices.

By embracing these innovative materials, manufacturers can not only meet the growing demand for sustainable products but also drive forward the development of cutting-edge technology in the years to come.