How Layer Count and Materials Impact Rigid-Flex PCB Design Costs

How layer count and materials impact rigid-flex PCB design costs is a crucial aspect of the electronics manufacturing process.

Understanding these factors can ensure efficient budgeting, optimal performance, and successful project outcomes.

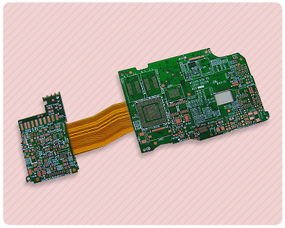

Rigid-flex printed circuit boards (PCBs) have gained popularity for their versatility and compact design.

However, they also come with specific complexities and cost considerations.

In this article, we’ll delve into how layer counts and material choices influence costs and how to navigate these factors effectively.

Understanding Rigid-Flex PCBs

Rigid-flex PCBs combine the benefits of rigid and flexible substrates, allowing for intricate designs that fit into compact spaces.

They are used in various applications, from medical devices to aerospace technology, owing to their durability and versatility.

However, the complexity of their design often comes with a higher price tag compared to traditional PCBs.

This brings us to two critical factors in cost assessment: layer count and materials.

The Role of Layer Count in Cost Determination

Layer count refers to the number of conductive layers within a PCB.

In rigid-flex designs, multiple layers are usually required to facilitate the necessary circuit complexity.

Here’s how layer count plays a significant role in cost determination:

1. Manufacturing Complexity

Adding more layers increases manufacturing complexity.

Each layer requires precise alignment, and additional processes are involved in connecting these layers.

For example, double-sided boards are simpler and more cost-effective than multilayer designs.

As the layer count increases, so does the likelihood of production errors, which can lead to further costs in rework and quality assurance.

2. Production Time

More layers necessitate longer production times.

Each layer must be processed separately, and consequently, longer timelines can increase costs for labor, overhead, and resource allocation.

For instance, a 6-layer rigid-flex PCB can take significantly longer to manufacture than a 2-layer design, impacting overall project timelines and costs.

3. Material Costs

Each additional layer requires more copper and substrate material, which directly adds to the expenses.

High-quality materials are essential for ensuring performance, particularly in applications requiring durability and flexibility.

Therefore, a higher layer count will not only drive up production complexity but also add material costs to the overall expenditure.

Impact of Material Selection on PCB Costs

The materials used in the creation of rigid-flex PCBs significantly influence costs.

Different substrates and bonding agents can vary widely in price, performance, and reliability.

Here’s how material selection impacts costs:

1. Substrate Choices

Common substrate materials such as FR-4, polyimide, or PTFE have different thermal and electrical properties, affecting both performance and cost.

FR-4 is relatively inexpensive and widely used, but for applications requiring higher thermal or electrical performance, polyimide might be necessary.

While polyimide can be double the cost of FR-4, its benefits often justify the expense for critical applications.

2. Layer Adhesives

The choice of adhesive materials also matters.

The adhesive layer plays a key role in forming a reliable bond between the rigid and flexible sections of a PCB.

High-performance adhesives can enhance durability and lifespan, but they typically come at a premium.

Selecting the right adhesive that balances performance with cost is crucial for a successful design.

3. Surface Finishes and Coatings

Surface finishes like ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling) can impact the to-total design cost as well.

ENIG is often preferred for complex designs due to its reliability but is more expensive than HASL.

The selection of surface finishes must consider the application requirements, as well as economic factors.

Budgeting for Rigid-Flex PCB Design

When budgeting for rigid-flex PCB design, it’s essential to consider the implications of layer count and materials closely.

Factors such as expected production volume, application requirements, and even potential post-production updates can heavily influence total costs. Here are some tips for effective budgeting:

1. Evaluate Design Requirements

Before initiating a design, assess the specific requirements of your project.

A thorough understanding of layer necessity and the ideal materials can lead to more informed decisions regarding complexity and budget constraints.

2. Seek Expert Guidance

Collaborating with PCB designers and manufacturers who specialize in rigid-flex technology is invaluable.

They can help identify optimal material choices and streamline the design process to help minimize unnecessary costs.

3. Iterate and Optimize

Don’t shy away from iterative design processes.

Prototyping allows for testing different layer counts and materials at a smaller scale to determine the most effective options before mass production.

Conclusion

Understanding how layer count and materials impact rigid-flex PCB design costs is fundamental for achieving both economic efficiency and product performance.

By carefully considering these factors in your design and budgeting processes, you can enhance the overall quality and reliability of your products while ensuring that you remain within financial constraints.

Awareness of the intricacies involved in rigid-flex PCB design not only drives costs but also empowers engineers and designers to make strategic decisions that align with both functionality and budget considerations.