Exploring the Benefits of IoT Integration with Rigid Flex PCBs

The Internet of Things (IoT) has revolutionized the way we interact with technology, allowing for seamless communication between devices and systems.

One of the key components that enable IoT functionality is the use of printed circuit boards (PCBs), which serve as the backbone for connecting various electronic components.

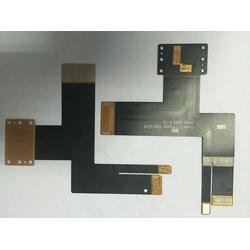

In recent years, there has been a growing trend towards using rigid flex PCBs in IoT devices due to their compact size and efficient design.

Rigid flex PCBs combine the benefits of both rigid and flexible PCBs, offering a unique solution for applications where space is limited and durability is essential.

By integrating rigid flex PCBs into IoT devices, manufacturers can create compact and lightweight products that are capable of withstanding harsh environments and demanding conditions.

This partnership between IoT and rigid flex PCBs has opened up new possibilities for designing innovative and reliable connected devices.

One of the key benefits of using rigid flex PCBs in IoT devices is their ability to reduce the overall size of the product.

Traditional rigid PCBs are limited by their flat, inflexible design, which can make it challenging to fit all the necessary components into a small space.

By incorporating flexible sections into the PCB, manufacturers can create more compact and streamlined designs that are better suited for IoT applications.

In addition to their compact size, rigid flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The flexible sections of the PCB help to absorb shock and vibration, reducing the risk of damage to the components.

This is particularly important for IoT devices that may be exposed to rough handling or extreme conditions.

By using rigid flex PCBs, manufacturers can ensure that their products are built to last and can withstand the rigors of everyday use.

Another advantage of integrating rigid flex PCBs into IoT devices is their ability to support complex and intricate designs.

The flexible sections of the PCB can be bent and folded to fit into tight spaces or conform to the shape of the device.

This flexibility allows for greater design freedom and opens up new possibilities for creating innovative and unique products.

Whether it’s a wearable device, a smart home appliance, or a connected industrial machine, rigid flex PCBs offer a versatile solution for bringing IoT concepts to life.

Furthermore, rigid flex PCBs are also more cost-effective in the long run.

While the initial manufacturing costs may be slightly higher than traditional PCBs, the durability and reliability of rigid flex PCBs can help to reduce maintenance and replacement costs over time.

This makes them a smart investment for manufacturers looking to create high-quality IoT devices that will stand the test of time.

In conclusion, the partnership between IoT and rigid flex PCBs offers a winning combination for creating compact, efficient, and reliable connected devices.

By leveraging the unique benefits of rigid flex PCBs, manufacturers can design innovative products that push the boundaries of what is possible in the world of IoT.

As the demand for smaller, smarter, and more durable IoT devices continues to grow, rigid flex PCBs will play an increasingly important role in shaping the future of connected technology.