Benefits of Integrating Rigid Flex PCBs into IoT Devices

The Internet of Things (IoT) has revolutionized the way we interact with technology, allowing for seamless connectivity between devices and the ability to gather and analyze data in real-time.

As the demand for smaller, more efficient IoT devices continues to grow, the need for innovative solutions in PCB design has become increasingly important.

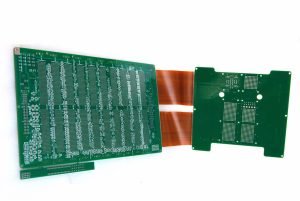

One such solution that has gained traction in recent years is the integration of rigid flex PCBs into IoT devices.

Rigid flex PCBs offer a unique combination of flexibility and durability, making them ideal for applications where space is limited and reliability is crucial.

By combining rigid and flexible PCB materials into a single design, manufacturers can create compact, lightweight devices that can withstand the rigors of everyday use.

This versatility allows for greater design flexibility, enabling engineers to create more complex and innovative IoT devices.

One of the key benefits of integrating rigid flex PCBs into IoT devices is improved reliability. Traditional PCBs are prone to failure due to factors such as vibration, temperature fluctuations, and mechanical stress.

Rigid flex PCBs, on the other hand, are designed to withstand these challenges, making them ideal for applications where reliability is paramount.

By using rigid flex PCBs in IoT devices, manufacturers can ensure that their products will perform consistently and reliably over time.

In addition to improved reliability, integrating rigid flex PCBs into IoT devices can also lead to cost savings.

While the initial cost of designing and manufacturing rigid flex PCBs may be higher than traditional PCBs, the long-term benefits far outweigh the upfront investment.

By reducing the need for additional components and connectors, manufacturers can streamline the production process and reduce overall manufacturing costs.

This cost savings can be passed on to consumers, making IoT devices more affordable and accessible to a wider audience.

Another benefit of integrating rigid flex PCBs into IoT devices is increased design flexibility.

Traditional PCBs are limited in terms of size and shape, making it difficult to create compact and innovative designs.

Rigid flex PCBs, on the other hand, can be customized to fit virtually any form factor, allowing engineers to create devices that are smaller, lighter, and more aesthetically pleasing.

This flexibility opens up a world of possibilities for IoT device manufacturers, enabling them to push the boundaries of design and create products that are truly unique.

As the demand for smaller, more efficient IoT devices continues to grow, the integration of rigid flex PCBs into IoT devices is expected to become increasingly common.

By leveraging the benefits of rigid flex PCB technology, manufacturers can create devices that are more reliable, cost-effective, and flexible than ever before.

With the right design and manufacturing processes in place, the future of IoT devices looks brighter than ever.