Benefits of Using Rigid Flex PCBs in Electronic Devices

In today’s fast-paced world, electronic devices are becoming increasingly complex and compact.

As a result, the demand for innovative solutions to accommodate these advancements is higher than ever.

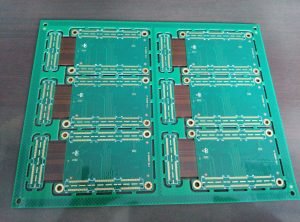

One such solution that has gained popularity in recent years is the use of rigid flex PCBs in electronic devices.

Rigid flex PCBs combine the best of both rigid and flexible PCBs, offering a unique solution that allows for greater design flexibility and reliability.

By incorporating both rigid and flexible sections into a single board, designers can create more compact and lightweight devices without sacrificing performance or durability.

One of the key benefits of using rigid flex PCBs in electronic devices is their ability to reduce the overall size and weight of the device.

By eliminating the need for bulky connectors and cables, rigid flex PCBs allow for more compact designs that are easier to integrate into a variety of applications. This can be particularly beneficial in industries such as aerospace, medical, and automotive, where space is at a premium.

In addition to their compact size, rigid flex PCBs also offer improved reliability compared to traditional PCBs.

By eliminating the need for soldered connections between rigid and flexible sections, rigid flex PCBs reduce the risk of mechanical failure and signal interference. This can result in higher performance and longer lifespan for electronic devices, ultimately saving time and money for manufacturers and consumers alike.

Another benefit of using rigid flex PCBs in electronic devices is their ability to withstand harsh environmental conditions.

The combination of rigid and flexible materials allows for greater flexibility and durability, making rigid flex PCBs ideal for applications that require resistance to vibration, shock, and temperature extremes. This can be particularly important in industries such as defense and aerospace, where reliability is critical.

Furthermore, rigid flex PCBs offer greater design flexibility compared to traditional PCBs.

By allowing for more complex and intricate designs, rigid flex PCBs enable designers to create innovative solutions that would not be possible with rigid or flexible PCBs alone. This can result in more efficient and cost-effective electronic devices that meet the specific needs of a wide range of industries.

Overall, the benefits of using rigid flex PCBs in electronic devices are clear.

From reduced size and weight to improved reliability and design flexibility, rigid flex PCBs offer a unique solution that can help manufacturers create cutting-edge electronic devices that meet the demands of today’s fast-paced world. Whether you are designing a new smartphone, medical device, or aerospace system, rigid flex PCBs can provide the innovative solution you need to stay ahead of the competition.