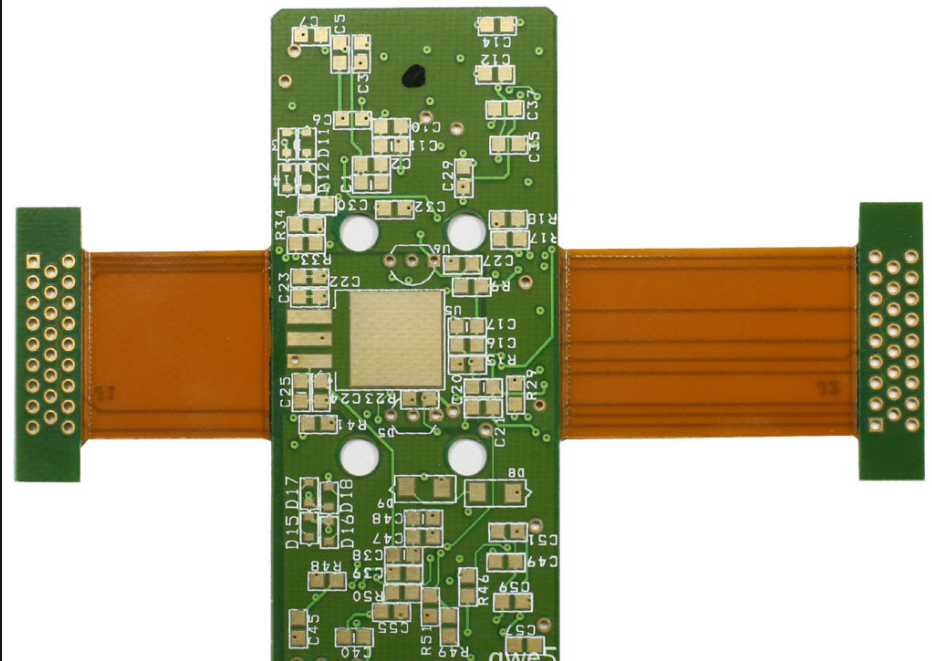

Innovations in Rigid-Flex PCB Manufacturing for AIoT Applications

The rapid expansion of the Artificial Intelligence of Things (AIoT) has driven significant advancements in the manufacturing of rigid-flex printed circuit boards (PCBs). These hybrid circuits, which combine the structural stability of rigid boards with the flexibility of flexible circuits, are essential for enabling the compact, high-performance devices that power AIoT ecosystems. To meet the growing demands of AIoT applications, manufacturers are adopting innovative techniques and materials that enhance the performance, reliability, and scalability of rigid-flex PCBs.

Advanced Manufacturing Techniques

One of the most notable innovations in rigid-flex PCB manufacturing is the adoption of laser drilling technology. Traditional mechanical drilling methods are limited in precision and can cause damage to delicate materials. Laser drilling, on the other hand, allows for the creation of microvias with diameters as small as 25 microns, enabling higher circuit density and improved signal integrity. This precision is particularly important for AIoT devices, where space is limited, and performance is critical. Additionally, laser drilling reduces production time and costs, making it a cost-effective solution for high-volume manufacturing.

Another groundbreaking technique is additive manufacturing, or 3D printing, which is revolutionizing the production of rigid-flex PCBs. This method allows for the rapid prototyping of complex designs, reducing development time and enabling manufacturers to quickly iterate and test new concepts. Additive manufacturing also minimizes material waste, aligning with the growing emphasis on sustainability in the electronics industry. For AIoT applications, this means faster time-to-market for innovative devices and the ability to customize designs for specific use cases.

Advanced Materials

The development of advanced materials is another key area of innovation in rigid-flex PCB manufacturing. High-temperature laminates, such as polyimide and liquid crystal polymer (LCP), are being used to improve the thermal and mechanical performance of rigid-flex PCBs. These materials can withstand extreme temperatures and harsh environments, making them ideal for industrial AIoT applications, such as smart factories and autonomous vehicles. Additionally, the use of conductive inks and adhesives enables the integration of embedded components, further reducing the size and weight of AIoT devices.

Another promising material innovation is the use of graphene-based conductive layers. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers exceptional electrical conductivity, mechanical strength, and flexibility. By incorporating graphene into rigid-flex PCBs, manufacturers can create circuits that are not only more efficient but also more durable. This is particularly beneficial for wearable AIoT devices, where flexibility and longevity are critical.

Embedded Components and System-in-Package (SiP)

The integration of embedded components within rigid-flex PCBs is a game-changer for AIoT applications. By embedding passive components, such as resistors and capacitors, directly into the PCB, manufacturers can reduce the overall size and weight of the device while improving signal integrity and reducing electromagnetic interference (EMI). This is especially important for AIoT devices, where compactness and performance are paramount.

System-in-Package (SiP) technology is another innovation that is transforming rigid-flex PCB manufacturing. SiP involves integrating multiple functional components, such as processors, memory, and sensors, into a single package. This approach not only reduces the footprint of the device but also enhances its performance by minimizing signal delays and power consumption. For AIoT applications, SiP enables the development of highly integrated devices that can process and transmit data more efficiently.

Automated Testing and Quality Control

As the complexity of rigid-flex PCBs increases, so does the need for advanced testing and quality control methods. Automated optical inspection (AOI) and X-ray inspection are being used to detect defects and ensure the reliability of rigid-flex PCBs. These techniques provide high-resolution images of the PCB, allowing manufacturers to identify issues such as misaligned components, solder joint defects, and microvia cracks. By implementing these advanced testing methods, manufacturers can ensure that their rigid-flex PCBs meet the stringent quality standards required for AIoT applications.

Sustainability in Manufacturing

Sustainability is becoming a key focus in the electronics industry, and rigid-flex PCB manufacturing is no exception. Manufacturers are adopting eco-friendly practices, such as using lead-free solders, biodegradable substrates, and water-based cleaning agents. Additionally, energy-efficient manufacturing processes, such as additive manufacturing and laser drilling, are reducing the environmental impact of PCB production. These sustainable practices not only align with global environmental goals but also appeal to consumers and businesses that prioritize green technology.

Conclusion

Innovations in rigid-flex PCB manufacturing are driving the development of next-generation AIoT devices. Advanced techniques such as laser drilling and additive manufacturing, along with the use of advanced materials and embedded components, are enabling the production of smaller, more efficient, and more reliable circuits. Automated testing and sustainability initiatives are further enhancing the quality and environmental impact of rigid-flex PCBs. As AIoT continues to evolve, these innovations will play a critical role in enabling smarter, more connected devices that transform industries and improve lives.