Benefits of Using Rigid Flex PCBs for Increased Reliability

In the ever-evolving world of technology, the demand for smart devices that can withstand harsh environments is on the rise.

From industrial machinery to medical equipment, these devices need to be reliable and durable to ensure optimal performance.

One key component that plays a crucial role in enhancing the reliability of these devices is the rigid flex PCB.

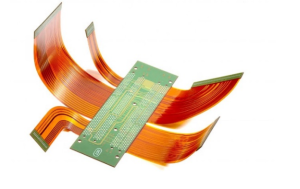

Rigid flex PCBs, also known as rigid-flexible printed circuit boards, combine the benefits of both rigid and flexible PCBs.

They consist of multiple layers of rigid and flexible substrates that are interconnected to form a single unit.

This unique design allows for greater flexibility in terms of layout and packaging, making them ideal for applications where space is limited.

One of the main benefits of using rigid flex PCBs is their robust design.

Unlike traditional PCBs, which are prone to damage from bending and twisting, rigid flex PCBs are more resistant to mechanical stress.

This makes them ideal for applications where the device may be subjected to vibrations, shocks, or other physical stresses.

Furthermore, the rigid flex design eliminates the need for connectors and cables, reducing the risk of signal interference and improving overall reliability.

By integrating the rigid and flexible components into a single unit, the risk of failure due to loose connections or broken wires is significantly reduced.

Another key advantage of rigid flex PCBs is their ability to withstand harsh environmental conditions.

Whether it’s extreme temperatures, humidity, or exposure to chemicals, rigid flex PCBs are designed to perform reliably in a wide range of environments.

This makes them ideal for applications in industries such as aerospace, automotive, and defense, where reliability is paramount.

In addition to their robust design and ability to withstand harsh environments, rigid flex PCBs also offer improved thermal performance.

The combination of rigid and flexible substrates allows for better heat dissipation, which helps prevent overheating and extends the lifespan of the device.

This is particularly important for high-performance applications where thermal management is critical.

Furthermore, the compact design of rigid flex PCBs allows for greater design flexibility and customization.

Manufacturers can create complex layouts and incorporate multiple components into a single unit, reducing the overall size and weight of the device.

This not only improves the aesthetics of the device but also enhances its functionality and performance.

Overall, the use of rigid flex PCBs offers a wide range of benefits for increasing the reliability of smart devices in harsh environments.

From their robust design and ability to withstand mechanical stress to their improved thermal performance and design flexibility, rigid flex PCBs are a key component in ensuring the longevity and performance of modern electronic devices.

As technology continues to advance and the demand for reliable smart devices grows, the importance of using rigid flex PCBs cannot be overstated.

Their unique design and superior performance make them an ideal choice for applications where reliability is paramount.

By investing in rigid flex PCBs, manufacturers can ensure that their devices will perform optimally in even the harshest of environments.