Increased Reliability: How Rigid-Flex PCBs Enhance Smart Device Durability

In the world of smart devices, reliability is a critical factor that directly impacts user satisfaction and product longevity.

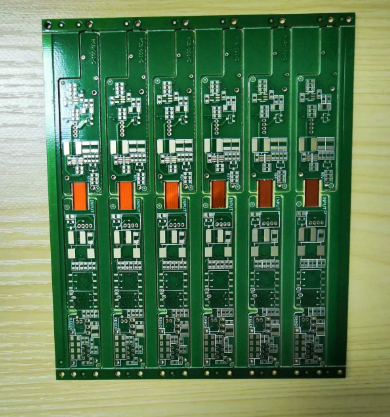

Rigid-flex printed circuit boards (PCBs) have gained widespread recognition for their ability to enhance the reliability of electronic devices, particularly in harsh or demanding environments. By combining the strength of rigid boards with the adaptability of flexible circuits, rigid-flex PCBs offer a robust design that can withstand mechanical stress, temperature fluctuations, and other environmental challenges.

One of the key reasons rigid-flex PCBs are more reliable than traditional PCBs is their reduced need for connectors and cables. In conventional designs, connectors and cables are often weak points that can fail due to wear, corrosion, or vibration.

Rigid-flex PCBs eliminate these components by integrating rigid and flexible sections into a single, seamless unit.

This not only reduces the risk of mechanical failure but also minimizes signal interference, ensuring consistent performance over time.

The durability of rigid-flex PCBs makes them ideal for applications in harsh environments.

For example, in the automotive industry, electronic systems are exposed to extreme temperatures, vibrations, and moisture.

Rigid-flex PCBs are designed to withstand these conditions, providing reliable performance in critical systems such as engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). Similarly, in aerospace and defense applications, rigid-flex PCBs can endure high levels of mechanical stress, radiation, and temperature variations, making them suitable for use in satellites, aircraft, and military equipment.

Another factor contributing to the increased reliability of rigid-flex PCBs is their ability to absorb and dissipate mechanical stress.

The flexible sections of the board act as shock absorbers, reducing the impact of vibrations and bending on the rigid components.

This is particularly important in wearable devices, such as fitness trackers and smartwatches, which are subjected to constant movement and bending.

By mitigating stress on the circuitry, rigid-flex PCBs ensure that these devices remain functional and durable over extended periods.

Rigid-flex PCBs also excel in thermal management, which is crucial for maintaining reliability in high-performance devices.

The integration of rigid and flexible sections allows for efficient heat dissipation, preventing overheating and prolonging the lifespan of components.

This is especially important in devices like smartphones, tablets, and IoT sensors, where compact designs and high power consumption can lead to thermal challenges.

Furthermore, the streamlined design of rigid-flex PCBs reduces the risk of human error during assembly.

With fewer components to connect and assemble, the likelihood of mistakes is significantly lower, resulting in fewer defects and higher-quality products.

This reliability extends to the end user, who benefits from a device that performs consistently and requires fewer repairs or replacements.

In conclusion, the robust design of rigid-flex PCBs significantly enhances the reliability of smart devices, particularly in harsh or demanding environments.

By eliminating weak points, absorbing mechanical stress, and improving thermal management, rigid-flex PCBs ensure that devices remain durable, functional, and dependable. As the demand for reliable electronics continues to grow, rigid-flex PCBs will play an increasingly important role in shaping the future of smart devices.