The Impact of AI on Rigid-Flex PCB Manufacturing Processes

Artificial Intelligence (AI) has been revolutionizing various industries, and the manufacturing sector is no exception.

In recent years, AI has been increasingly utilized in the production of Rigid-Flex Printed Circuit Boards (PCBs) to optimize manufacturing processes and improve overall efficiency.

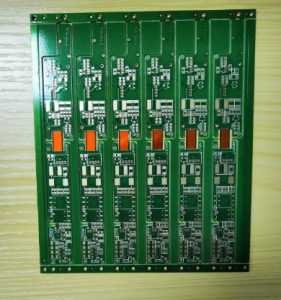

Rigid-Flex PCBs are a type of PCB that combines both rigid and flexible board materials, allowing for more compact and lightweight designs in electronic devices.

The integration of AI in the manufacturing of Rigid-Flex PCBs has led to significant advancements in quality control, production speed, and cost reduction.

One of the key ways in which AI is optimizing Rigid-Flex PCB manufacturing processes is through predictive maintenance.

By analyzing data from sensors and monitoring equipment, AI algorithms can predict when a machine is likely to fail and schedule maintenance before a breakdown occurs.

This proactive approach to maintenance not only reduces downtime but also extends the lifespan of equipment, ultimately leading to cost savings for manufacturers.

In addition to predictive maintenance, AI is also being used to improve quality control in Rigid-Flex PCB manufacturing.

AI algorithms can analyze images of PCBs to detect defects such as cracks, soldering issues, and misalignments.

By automating the inspection process, manufacturers can identify and address quality issues more quickly and accurately, resulting in higher-quality products and fewer defects.

Furthermore, AI is helping to optimize production speed in Rigid-Flex PCB manufacturing.

By analyzing historical production data and real-time information from the manufacturing floor, AI algorithms can identify bottlenecks in the production process and suggest ways to streamline operations.

This data-driven approach to production planning and scheduling enables manufacturers to increase throughput and meet tight deadlines more efficiently.

Another area where AI is making a significant impact on Rigid-Flex PCB manufacturing processes is in material optimization.

By analyzing data on material usage, waste, and costs, AI algorithms can recommend the most cost-effective materials to use for specific PCB designs.

This not only helps manufacturers reduce material waste but also lowers production costs and improves overall profitability.

Overall, the integration of AI in Rigid-Flex PCB manufacturing processes is transforming the industry by enhancing quality control, optimizing production speed, and reducing costs.

By leveraging AI technologies, manufacturers can stay competitive in a rapidly evolving market and meet the growing demand for high-quality, reliable Rigid-Flex PCBs.

As AI continues to advance, we can expect to see even more innovations in Rigid-Flex PCB manufacturing that will further improve efficiency and drive growth in the industry.