Benefits of High-Performance Rigid Flex PCB Manufacturing Services

High-performance rigid flex PCB manufacturing services offer a wide range of benefits for companies looking to create advanced electronic devices.

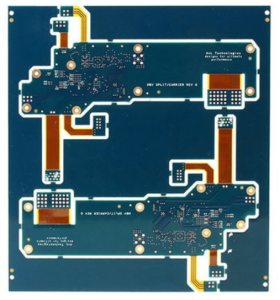

These services combine the flexibility of flexible PCBs with the durability of rigid PCBs, resulting in a versatile and reliable solution for a variety of applications.

One of the key benefits of high-performance rigid flex PCB manufacturing services is the ability to create complex designs that would be difficult or impossible to achieve with traditional PCBs. The combination of rigid and flexible sections allows for greater design flexibility, enabling engineers to create compact and efficient layouts that maximize space and performance.

In addition to design flexibility, high-performance rigid flex PCBs offer improved reliability compared to traditional PCBs.

The rigid sections provide support and stability for components, reducing the risk of damage from vibration, shock, and other environmental factors.

At the same time, the flexible sections allow for greater flexibility and movement, reducing the risk of stress on components during operation.

Another benefit of high-performance rigid flex PCB manufacturing services is the ability to reduce assembly time and costs.

By combining multiple PCBs into a single unit, manufacturers can streamline the assembly process and reduce the number of interconnects required.

This not only saves time and labor costs but also reduces the risk of errors and defects during assembly.

High-performance rigid flex PCBs also offer improved signal integrity and electrical performance compared to traditional PCBs.

The combination of rigid and flexible sections allows for better control of impedance, signal routing, and crosstalk, resulting in higher performance and reliability for electronic devices. This is especially important for high-speed and high-frequency applications where signal integrity is critical.

Furthermore, high-performance rigid flex PCB manufacturing services can help companies reduce the overall size and weight of their electronic devices.

By combining rigid and flexible sections into a single unit, manufacturers can create more compact and lightweight designs that are ideal for portable and space-constrained applications. This can help companies create smaller, more portable devices without sacrificing performance or reliability.

Overall, high-performance rigid flex PCB manufacturing services offer a wide range of benefits for companies looking to create advanced electronic devices. From improved design flexibility and reliability to reduced assembly time and costs, these services provide a versatile and reliable solution for a variety of applications. By leveraging the unique capabilities of rigid flex PCBs, companies can create high-performance electronic devices that meet the demands of today’s fast-paced and competitive market.