Optimizing Rigid Flex PCBs for High-Frequency Performance

In the world of modern communication devices, high-frequency performance is crucial for ensuring fast and reliable data transmission.

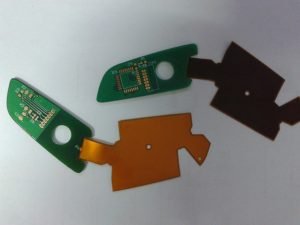

Rigid flex PCBs, with their unique combination of rigid and flexible materials, offer a versatile solution for optimizing high-frequency performance in electronic devices.

By carefully designing and manufacturing rigid flex PCBs, engineers can achieve the high-speed signal integrity required for today’s advanced communication technologies.

One of the key factors in optimizing rigid flex PCBs for high-frequency performance is the selection of materials.

High-quality materials with low dielectric constant and low loss tangent are essential for minimizing signal loss and maintaining signal integrity at high frequencies.

By choosing the right materials for both the rigid and flexible portions of the PCB, engineers can ensure that the electrical properties of the board are optimized for high-speed data transmission.

In addition to selecting the right materials, the design of the rigid flex PCB also plays a critical role in achieving high-frequency performance.

Careful attention must be paid to the layout of the board, including the placement of components, traces, and vias.

By minimizing signal reflections, crosstalk, and impedance mismatches, engineers can reduce signal degradation and improve the overall performance of the PCB at high frequencies.

Furthermore, the manufacturing process of rigid flex PCBs must be carefully controlled to ensure high-frequency performance.

Precision fabrication techniques, such as laser drilling and controlled impedance routing, are essential for maintaining signal integrity and minimizing signal loss.

By working closely with experienced PCB manufacturers, engineers can ensure that their rigid flex PCBs are manufactured to the highest standards of quality and performance.

Another important consideration in optimizing rigid flex PCBs for high-frequency performance is thermal management.

High-frequency signals can generate heat, which can affect the electrical properties of the board and lead to signal degradation.

By incorporating thermal management techniques, such as heat sinks, thermal vias, and proper ventilation, engineers can ensure that their rigid flex PCBs operate at peak performance even under high-frequency conditions.

Overall, rigid flex PCBs offer a versatile and reliable solution for optimizing high-frequency performance in modern communication devices.

By carefully selecting materials, designing the board layout, controlling the manufacturing process, and implementing thermal management techniques, engineers can achieve the high-speed signal integrity required for today’s advanced communication technologies. With the right expertise and attention to detail, rigid flex PCBs can be optimized for high-frequency applications, making them an ideal choice for a wide range of electronic devices.