Hidden Costs in Rigid-Flex PCB Design and How to Avoid Them

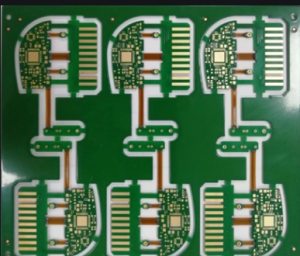

Rigid-flex PCB design is increasingly popular in various industries due to its unique combination of flexibility and durability.

However, while this technology offers numerous advantages, it also comes with potential hidden costs that can impact your project’s budget and timeline.

Understanding these hidden costs is essential for project managers and engineers looking to design effective and cost-efficient rigid-flex PCBs.

Understanding Rigid-Flex PCB Design

Rigid-flex PCBs seamlessly integrate flexible and rigid circuit board materials, allowing them to bend and conform to compact spaces.

This feature makes them ideal for applications in smartphones, wearable technology, and even in aerospace.

However, the complexity of these designs requires meticulous planning and execution, which often leads to overlooked expenses.

Common Hidden Costs in Rigid-Flex PCB Design

1. Material Costs

One of the most significant hidden costs in rigid-flex PCB design arises from materials.

While standard PCBs typically utilize inexpensive FR-4 laminates, rigid-flex boards demand advanced materials that can withstand bending cycles while maintaining integrity.

Materials such as polyimide can be considerably more expensive than traditional options. Additionally, sourcing specialized laminates and prepregs can further drive up costs.

2. Manufacturing Complexity

Manufacturing rigid-flex PCBs often requires advanced fabrication techniques, which can lead to increased labor costs.

The intricate nature of the designs can necessitate additional time for setup and processing, often inflating the final manufacturing bill.

Also, working with multiple layers and different thicknesses can complicate the manufacturing process, further adding to costs.

3. Testing Expenses

Given the complexity of rigid-flex designs, thorough testing is crucial to ensure reliability and performance.

Hidden costs can accumulate during the testing phase since specialized equipment is often needed to evaluate the boards rigorously.

Furthermore, failure to identify defects during testing can lead to costly reworks or even product recalls, emphasizing the importance of robust testing protocols from the outset.

4. Design Iterations

Rigid-flex designs typically demand more iterations compared to standard PCBs.

Each design modification requires time and resources, and if these changes happen late in the development process, they can lead to significant overruns in both time and budget.

Frequent changes may signal a lack of clarity in design objectives or an understanding of the capabilities of flexible materials, both of which can incur additional costs.

Strategies to Avoid Hidden Costs

1. Thorough Planning

One of the best ways to avoid hidden costs is to engage in detailed planning from the outset.

Utilize design simulations and prototypes to gain insights into how your rigid-flex PCB will perform in real-world applications.

Engage cross-functional teams early in the design process to align on requirements and avoid costly adjustments later.

2. Selecting the Right Materials

Investing time in understanding and selecting appropriate materials can significantly influence the overall cost.

It’s vital to analyze not just the upfront costs but also the long-term performance and durability of the materials you choose. Work closely with your suppliers to identify materials that deliver the necessary performance without breaking the budget.

3. Utilizing Technology

Leverage CAD and design software tailored for rigid-flex PCB design to streamline the process.

These tools can minimize design iteration cycles by allowing for easy modifications and visual inspections, reducing the likelihood of errors that lead to costly fixes later on.

4. Comprehensive Testing Plans

Develop a thorough testing plan early in the project to ensure that all potential weaknesses are addressed before production.

Factor in the cost of advanced testing equipment and methodologies to avoid unexpected expenses down the line.

Early testing can often catch issues before they escalate, saving both time and money.

Conclusion

Rigid-flex PCB design presents a wealth of opportunities but also comes with hidden costs that can hinder project success.

By understanding these potential pitfalls and employing strategic planning, thoughtful material selection, effective use of technology, and comprehensive testing, you can mitigate risks and ensure that your rigid-flex PCB design project stays on budget and on schedule. Adopting these practices will not only help you to avoid unnecessary expenses but also enhance the overall quality and performance of your final product.