Benefits of Using Rigid Flex PCBs in Wearable Technology

Wearable technology has become increasingly popular in recent years, with devices like smartwatches, fitness trackers, and health monitors becoming ubiquitous in our daily lives. These devices rely on advanced electronics to function, and one key component that is essential for their operation is the printed circuit board (PCB). PCBs are used to connect and support the electronic components that make up these devices, and they play a crucial role in ensuring that the devices function properly.

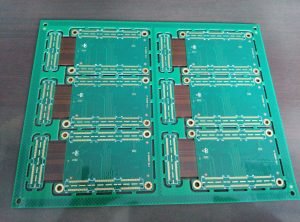

One type of PCB that is particularly well-suited for wearable technology is the rigid flex PCB.

Rigid flex PCBs combine the benefits of both rigid and flexible PCBs, offering a unique combination of durability, flexibility, and reliability.

This makes them an ideal choice for wearable devices, which need to be able to withstand the rigors of daily use while also being comfortable and unobtrusive to wear.

One of the key benefits of using rigid flex PCBs in wearable technology is their durability.

Traditional rigid PCBs are prone to breaking or cracking when bent or twisted, which can be a major problem for wearable devices that need to be able to move and flex with the wearer’s body. Rigid flex PCBs, on the other hand, are designed to be able to bend and flex without breaking, making them much more durable and reliable for use in wearable devices.

In addition to their durability, rigid flex PCBs also offer a high level of flexibility.

This flexibility allows designers to create devices that are more comfortable and ergonomic to wear, as the PCB can be shaped to fit the contours of the body. This is particularly important for wearable devices that need to be worn for long periods of time, as comfort is a key factor in ensuring that users will continue to use the device.

Another benefit of using rigid flex PCBs in wearable technology is their reliability.

The flexible portions of the PCB are typically made from polyimide, a material that is highly resistant to heat, chemicals, and moisture.

This makes rigid flex PCBs much more reliable in harsh environments, such as those encountered in wearable devices that may be exposed to sweat, water, or extreme temperatures.

Overall, the use of rigid flex PCBs in wearable technology offers a number of benefits, including durability, flexibility, and reliability.

These benefits make rigid flex PCBs an ideal choice for designers looking to create wearable devices that are comfortable, durable, and reliable for everyday use. By harnessing the potential of rigid flex PCBs, designers can create innovative and cutting-edge wearable technology that meets the needs of today’s consumers.