Benefits of Rigid-Flex Assembly Technology in Manufacturing Processes

In the world of manufacturing, efficiency is key. Companies are constantly looking for ways to streamline their processes and reduce costs while maintaining high quality standards. One technology that has been gaining popularity in recent years is rigid-flex assembly technology.

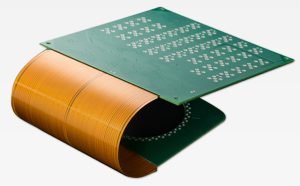

This innovative approach to manufacturing combines the benefits of rigid and flexible circuit boards, allowing for greater design flexibility and reduced assembly time.

One of the main benefits of rigid-flex assembly technology is its ability to simplify the manufacturing process.

Traditional circuit board assembly involves multiple steps, including soldering components onto the board and connecting them with wires.

With rigid-flex technology, many of these steps can be eliminated, as the components are directly mounted onto the flexible substrate.

This not only reduces the risk of errors during assembly but also speeds up the production process.

Another advantage of rigid-flex assembly technology is its ability to reduce the overall size and weight of the final product.

By combining rigid and flexible circuit boards into a single unit, manufacturers can create more compact and lightweight devices.

This is particularly important in industries such as aerospace and medical devices, where space and weight constraints are critical.

Furthermore, rigid-flex technology offers greater design flexibility compared to traditional circuit board assembly methods.

Manufacturers can create complex, three-dimensional designs that would be impossible with rigid boards alone.

This allows for more innovative and efficient product designs, leading to improved performance and functionality.

In addition to these benefits, rigid-flex assembly technology also offers cost savings for manufacturers.

By reducing the number of components and assembly steps required, companies can lower their production costs and improve their bottom line.

This is particularly important in today’s competitive market, where companies are constantly looking for ways to reduce costs and increase efficiency.

Overall, rigid-flex assembly technology offers a number of benefits for manufacturers looking to streamline their processes and improve their products.

By combining the advantages of rigid and flexible circuit boards, companies can create more compact, lightweight, and innovative designs while reducing costs and improving efficiency.

As technology continues to advance, rigid-flex assembly is likely to become an increasingly important tool for manufacturers looking to stay ahead of the competition.