Benefits of Using Rigid Flex PCBs in IoT Devices

The Internet of Things (IoT) has revolutionized the way we interact with technology, allowing for seamless communication between devices and the ability to collect and analyze data in real-time.

As IoT devices become more prevalent in our daily lives, the demand for smaller, more efficient, and reliable components has increased.

One such component that has gained popularity in IoT applications is the rigid flex PCB.

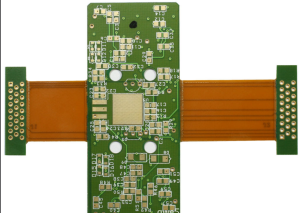

Rigid flex PCBs combine the benefits of both rigid and flexible PCBs, offering a unique solution for devices that require a combination of both.

These boards are made up of multiple layers of rigid and flexible materials that are interconnected to form a single unit.

This design allows for greater flexibility in the layout of components, as well as improved reliability and durability compared to traditional PCBs.

One of the key benefits of using rigid flex PCBs in IoT devices is their ability to reduce the overall size and weight of the device.

By combining the rigid and flexible components into a single unit, designers can create more compact and lightweight devices that are easier to integrate into a variety of applications.

This is especially important in IoT devices, where space is often limited and every millimeter counts.

In addition to their compact size, rigid flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The flexible components of the board help to absorb shock and vibration, reducing the risk of damage to the components and extending the lifespan of the device.

This is crucial in IoT applications, where devices are often exposed to harsh environments and must be able to withstand constant use.

Another benefit of using rigid flex PCBs in IoT devices is their ability to improve signal integrity and reduce electromagnetic interference.

The rigid components of the board provide a stable platform for high-speed signals, while the flexible components help to reduce crosstalk and interference between components.

This results in improved performance and reliability for the device, ensuring that data is transmitted accurately and efficiently.

Manufacturing rigid flex PCBs for IoT applications requires a high level of expertise and precision.

Designers must carefully plan the layout of components and ensure that the rigid and flexible materials are properly interconnected to create a reliable and durable board.

This process involves a combination of advanced manufacturing techniques, including laser drilling, plating, and lamination, to create a seamless integration of rigid and flexible components.

Despite the complexity of manufacturing rigid flex PCBs, the benefits of using these boards in IoT devices far outweigh the challenges.

By reducing the size and weight of devices, improving reliability and durability, and enhancing signal integrity, rigid flex PCBs offer a unique solution for designers looking to create cutting-edge IoT applications.

As the demand for smaller, more efficient, and reliable components continues to grow, rigid flex PCBs will play an increasingly important role in shaping the future of IoT technology.