Flex vs. Rigid-Flex: Choosing the Right PCB for Your Application

Printed circuit boards (PCBs) are an essential component in many electronic devices, serving as the foundation for connecting and supporting various electronic components. When it comes to choosing the right PCB for your application, one of the key decisions you’ll need to make is whether to go with a flexible PCB or a rigid-flex PCB. Both types of PCBs have their own unique advantages and disadvantages, so it’s important to understand the differences between the two before making a decision.

Flexible PCBs, as the name suggests, are designed to be flexible and bendable. They are made of a thin, flexible substrate material such as polyimide, which allows them to be bent or twisted to fit into tight spaces or conform to the shape of the device they are being used in. Flexible PCBs are ideal for applications where space is limited or where the PCB needs to be able to move or flex during operation.

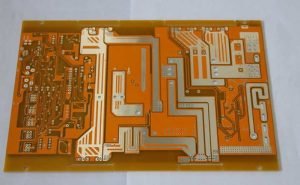

On the other hand, rigid-flex PCBs combine the benefits of both rigid and flexible PCBs. They consist of multiple layers of rigid PCB material connected by flexible PCB sections, allowing them to be both rigid and flexible at the same time. Rigid-flex PCBs are ideal for applications where the PCB needs to be able to bend or flex in certain areas while remaining rigid in others, such as in wearable devices or aerospace applications.

When deciding between a flexible PCB and a rigid-flex PCB for your application, there are several factors to consider. One of the main factors to consider is the level of flexibility required for your application. If your PCB needs to be able to bend or flex significantly, a flexible PCB may be the better option. However, if your PCB only needs to be able to bend or flex in certain areas, a rigid-flex PCB may be more suitable.

Another factor to consider is the complexity of your PCB design. Flexible PCBs are generally easier to design and manufacture than rigid-flex PCBs, as they consist of a single layer of flexible substrate material. Rigid-flex PCBs, on the other hand, are more complex to design and manufacture due to the multiple layers of rigid and flexible material involved. If your PCB design is relatively simple, a flexible PCB may be the more cost-effective option. However, if your PCB design is more complex and requires both rigid and flexible sections, a rigid-flex PCB may be necessary.

Cost is also an important factor to consider when choosing between a flexible PCB and a rigid-flex PCB. Flexible PCBs are generally more cost-effective than rigid-flex PCBs, as they require less material and are easier to manufacture. However, if the flexibility and durability of a rigid-flex PCB are necessary for your application, the higher cost may be justified.

In conclusion, when choosing between a flexible PCB and a rigid-flex PCB for your application, it’s important to consider factors such as the level of flexibility required, the complexity of your PCB design, and cost. Both types of PCBs have their own unique advantages and disadvantages, so it’s important to weigh these factors carefully before making a decision. By understanding the differences between flexible and rigid-flex PCBs, you can choose the right PCB for your application and ensure the success of your electronic device.