Benefits of Flex-Rigid PCBs in Aerospace Electronics

Flex-rigid PCBs, also known as flexible printed circuit boards, have become an essential component in the aerospace industry.

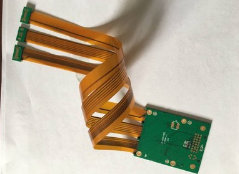

These innovative circuit boards offer a unique combination of flexibility and rigidity, making them ideal for use in the demanding environments of aerospace electronics.

In this article, we will explore the benefits of flex-rigid PCBs in aerospace electronics and how they are shaping the future of the industry.

One of the key advantages of flex-rigid PCBs in aerospace electronics is their ability to withstand extreme temperatures and vibrations.

Aerospace applications often involve harsh operating conditions, including rapid temperature changes and intense vibrations.

Flex-rigid PCBs are designed to be highly durable and reliable, making them well-suited for use in these challenging environments.

Their flexible nature allows them to bend and flex without breaking, while their rigid sections provide stability and support for critical components.

Another benefit of flex-rigid PCBs in aerospace electronics is their compact size and lightweight design.

Space is at a premium in aerospace applications, and traditional rigid PCBs can be bulky and cumbersome.

Flex-rigid PCBs offer a more streamlined and efficient solution, allowing for more compact and lightweight electronic systems.

This not only helps to reduce the overall weight of the aircraft, but also allows for more efficient use of space within the electronics enclosure.

Flex-rigid PCBs also offer improved signal integrity and reduced electromagnetic interference (EMI) in aerospace electronics.

The flexible nature of these circuit boards allows for tighter routing of signal traces, reducing signal loss and improving overall performance.

Additionally, the rigid sections of the PCBs help to shield sensitive components from external EMI, ensuring that the electronics operate reliably and accurately in high-noise environments.

In addition to their technical benefits, flex-rigid PCBs also offer cost savings and faster time-to-market for aerospace electronics manufacturers.

The streamlined design and reduced component count of flex-rigid PCBs can lead to lower production costs and shorter lead times.

This is especially important in the fast-paced aerospace industry, where time-to-market is a critical factor in staying competitive.

Overall, flex-rigid PCBs are revolutionizing the way aerospace electronics are designed and manufactured.

Their unique combination of flexibility, rigidity, and durability make them an ideal choice for a wide range of aerospace applications.

From commercial aircraft to military drones, flex-rigid PCBs are the backbone of next-generation aerospace electronics.

In conclusion, the benefits of flex-rigid PCBs in aerospace electronics are clear.

These innovative circuit boards offer a unique combination of flexibility, rigidity, and durability that make them ideal for use in the demanding environments of aerospace applications.

With improved signal integrity, reduced EMI, compact size, and cost savings, flex-rigid PCBs are shaping the future of the aerospace industry.

As technology continues to advance, flex-rigid PCBs will play an increasingly important role in the development of next-generation aerospace electronics.