Benefits of Using Flex Rigid PCBs in Industrial Applications

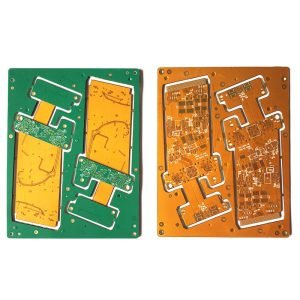

Flex rigid PCBs, also known as flexible printed circuit boards, are becoming increasingly popular in industrial applications due to their numerous benefits. These innovative circuit boards offer a combination of flexibility and rigidity, making them ideal for use in environments where space is limited and where the board needs to be able to bend or twist without breaking. In this article, we will explore the benefits of using flex rigid PCBs in industrial applications.

One of the key advantages of flex rigid PCBs is their ability to save space. Traditional rigid PCBs are limited in terms of how they can be shaped and positioned within a device or piece of equipment. Flex rigid PCBs, on the other hand, can be bent or twisted to fit into tight spaces or odd shapes, allowing for more efficient use of space and a more compact design overall. This can be particularly useful in industrial applications where space is at a premium.

Another benefit of using flex rigid PCBs in industrial applications is their durability. These circuit boards are designed to withstand harsh environments, including high temperatures, vibrations, and moisture. This makes them ideal for use in industrial equipment that is exposed to these types of conditions on a regular basis. Flex rigid PCBs are also less prone to damage from bending or twisting, making them a more reliable option for industrial applications where the board may need to flex during operation.

Flex rigid PCBs are also highly customizable, allowing for a greater degree of design flexibility compared to traditional rigid PCBs. This means that manufacturers can create circuit boards that are tailored to the specific needs of their industrial applications, whether that means incorporating unique shapes, sizes, or features. This level of customization can lead to improved performance and efficiency in industrial equipment, ultimately resulting in cost savings and a competitive edge in the market.

In addition to their space-saving design, durability, and customization options, flex rigid PCBs also offer improved signal integrity. These circuit boards are designed to minimize signal loss and interference, resulting in more reliable performance and better overall functionality. This is particularly important in industrial applications where precise communication between components is essential for the proper operation of equipment.

Overall, the benefits of using flex rigid PCBs in industrial applications are clear. These innovative circuit boards offer a unique combination of flexibility, durability, customization, and signal integrity that make them an ideal choice for a wide range of industrial equipment and devices. As technology continues to advance and industrial applications become more complex, flex rigid PCBs will likely play an increasingly important role in ensuring the reliability and efficiency of industrial equipment.