Benefits of Using Flex Rigid PCBs in Aerospace and Defense Applications

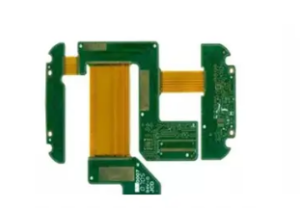

Flex rigid PCBs, or flexible printed circuit boards, have become increasingly popular in aerospace and defense applications due to their numerous benefits. These specialized PCBs offer a unique combination of flexibility and rigidity, making them ideal for use in environments where space is limited and durability is crucial. In this article, we will explore the advantages of using flex rigid PCBs in aerospace and defense applications.

One of the key benefits of flex rigid PCBs is their ability to be bent or twisted without breaking. This flexibility allows for greater design freedom, as these PCBs can be shaped to fit into tight spaces or conform to the contours of a specific component. In aerospace and defense applications, where space is often at a premium, this flexibility can be a game-changer. Flex rigid PCBs can be used to create compact, lightweight electronic systems that would be impossible to achieve with traditional rigid PCBs.

In addition to their flexibility, flex rigid PCBs also offer superior durability and reliability. The combination of flexible and rigid layers in these PCBs results in a stronger, more resilient board that can withstand harsh environmental conditions, such as extreme temperatures, vibrations, and shock. This makes flex rigid PCBs ideal for use in aerospace and defense applications, where reliability is paramount. These PCBs are less prone to failure due to their robust construction, ensuring that critical electronic systems remain operational even in the most challenging conditions.

Another advantage of using flex rigid PCBs in aerospace and defense applications is their ability to reduce weight and size. Traditional rigid PCBs can be bulky and heavy, limiting their use in applications where weight and space are critical factors. Flex rigid PCBs, on the other hand, are lightweight and compact, making them ideal for use in aircraft, satellites, and other aerospace and defense systems where every ounce counts. By using flex rigid PCBs, engineers can design smaller, lighter electronic systems without sacrificing performance or reliability.

Furthermore, flex rigid PCBs offer improved signal integrity and reduced electromagnetic interference (EMI). The flexible layers in these PCBs help to minimize signal loss and crosstalk, resulting in cleaner, more reliable signals. This is especially important in aerospace and defense applications, where electronic systems must operate flawlessly in high-stress environments. Additionally, the rigid layers in flex rigid PCBs provide shielding against EMI, further enhancing the performance and reliability of these boards.

In conclusion, flex rigid PCBs offer a wide range of benefits for aerospace and defense applications. Their flexibility, durability, lightweight construction, and improved signal integrity make them an ideal choice for use in electronic systems where space is limited and reliability is crucial. By using flex rigid PCBs, engineers can design innovative, high-performance electronic systems that meet the demanding requirements of the aerospace and defense industries. As technology continues to advance, flex rigid PCBs will undoubtedly play a key role in shaping the future of aerospace and defense electronics.