Benefits of Flex-Rigid PCBs in UAVs

Flex-rigid PCBs, or flexible printed circuit boards, have been gaining popularity in the aerospace industry, particularly in the design and manufacturing of unmanned aerial vehicles (UAVs).

These innovative PCBs offer a number of benefits that can significantly enhance the performance and reliability of UAVs, making them an ideal choice for mission-critical applications.

One of the key advantages of using flex-rigid PCBs in UAVs is their ability to withstand harsh environmental conditions.

UAVs are often deployed in challenging environments, such as extreme temperatures, high humidity, and vibration.

Traditional rigid PCBs may not be able to withstand these conditions, leading to performance issues and potential failures.

Flex-rigid PCBs, on the other hand, are designed to be more durable and reliable, making them well-suited for use in UAVs.

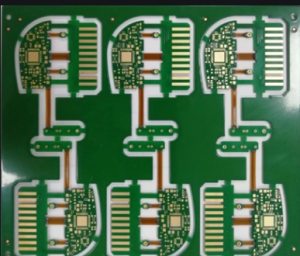

In addition to their durability, flex-rigid PCBs also offer greater design flexibility. UAVs are typically compact and lightweight, requiring PCBs that can be customized to fit into tight spaces and conform to complex shapes.

Flex-rigid PCBs can be bent, twisted, and folded to fit the specific requirements of a UAV, allowing for more efficient use of space and improved performance.

Furthermore, flex-rigid PCBs can help reduce the overall weight of a UAV.

Weight is a critical factor in the design of UAVs, as lighter aircraft can fly longer distances and carry heavier payloads.

By using flex-rigid PCBs, designers can create lighter and more compact UAVs without sacrificing performance or reliability.

Another benefit of using flex-rigid PCBs in UAVs is their ability to improve signal integrity.

UAVs rely on a complex network of sensors, communication systems, and other electronic components to navigate and perform their missions.

Poor signal integrity can lead to communication errors, data loss, and other performance issues.

Flex-rigid PCBs are designed to minimize signal interference and maintain signal integrity, ensuring that UAVs can operate effectively in a variety of environments.

In addition to these benefits, flex-rigid PCBs can also help reduce the overall cost of manufacturing UAVs.

Traditional rigid PCBs require multiple layers and complex assembly processes, which can be time-consuming and expensive.

Flex-rigid PCBs, on the other hand, are simpler to manufacture and assemble, resulting in lower production costs and faster time-to-market for UAVs.

Overall, the use of flex-rigid PCBs in UAVs offers a number of significant benefits that can enhance performance and reliability.

From their durability and design flexibility to their weight savings and signal integrity improvements, flex-rigid PCBs are an ideal choice for mission-critical applications in the aerospace industry.

As the demand for UAVs continues to grow, the use of flex-rigid PCBs is likely to become even more widespread, shaping the future of UAV technology for years to come.